株式会社和田製作所

| Exhibitor name |

株式会社和田製作所

Wada Manufacturing Co. ,Ltd

|

|---|---|

| Booth NO. | 4-541-113 |

| Address |

〒720-0017 広島県 福山市千田町4-17-23 4-17-23,senda,fukuyama,hirosima,720-0017 |

| Website | https://www.wadass.co.jp |

| Phone number | +81-8-4970-0038 |

| PR message | Our company specializes in metal press processing, from die design to mass production. We showcase deep drawing technology with samples from fingertip to hand size. Our progressive die deep drawing ensures high precision and quality. Explore our advanced press technology at our exhibit. |

| The Main Item |

|

| Movie |

|

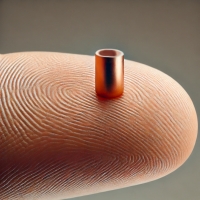

| The name of Item[1] | Precision deep-drawn parts using progressive dies |

| Details[1] |

Die: Progressive die Size: Fits on fingertip Shape: Cylindrical drawing Material: Copper Precision level: Medium to high *The photo is an image |

| The name of Item[2] | Small cylindrical drawing that fits on your fingertips |

| Details[2] |

The smaller the workpiece, the finer it becomes, and dimensional precision is required. Furthermore, aluminum and nickel are prone to problems such as tearing, making them more difficult. Wada Seisakusho can mass-produce nickel using a progressive die. Square tubes are more difficult than cylindrical tubes because tension is placed on the corners. Die: Progressive, single shot possible Size: Fingertip size Material: Aluminum, nickel, brass R: Inside 0.5, outside 1.0 Accuracy: Medium |

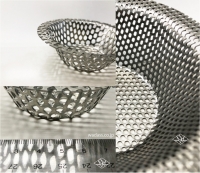

| The name of Item[3] | Punching material drawing technology (secondary processing of punching material) |

| Details[3] |

・Tapered shape ・Dish shape ・Square tube, cylindrical shape We will bring samples of each shape to the venue. Common uses for punched drawing are metal filters, strainers, and sieves. Wada Seisakusho has a track record of drawing 30 times in a row on a single punched material. For inquiries about secondary processing of punched material, please visit the Wada Seisakusho booth. |

| The name of Item[4] | Mass production technology for nickel deep-drawn parts |

| Details[4] |

Pure nickel, which is feared to be tough and difficult to cut, is said to have good ductility (the ability to stretch plastically) and is compatible with press processing, but in reality, the difficulty of mass-producing it increases just like with other difficult-to-cut materials. With a tougher material than pure nickel, Wada Seisakusho has made mass production possible with progressive processing. Size: Fingertip size Mold: Progressive mold Material: Pure nickel |

| The name of Item[5] | Multi-stage + irregular square cylinder drawing technology |

| Details[5] |

Complex parts with small radii, such as multi-step parts and lugs, are subjected to tension, so technology is required to prevent them from tearing. Often used for covers. Mold: Single-shot type Material: Iron, aluminum Size: One to two hands Precision: Medium |

| The name of Item[6] | Ring shape made by pressing!? Cutting-less method conversion technology |

| Details[6] |

If it is manufactured by cutting, it may be possible to press it. By changing the manufacturing method from cutting to pressing, there are the following advantages. 1. Cost reduction Processing time is shortened, and manufacturing costs can be reduced. Cutting tools wear out and are less frequently replaced. 2. Productivity improvement Mass production is possible with a single press. Automation is possible. Processing can be done in less time than cutting, making it easier to mass-produce. Size: The width of two fingertips Mold: Progressive mold Accuracy: High *The photo is for illustrative purposes only. |

| The name of Item[7] | A tiny cylindrical drawing that fits on your fingertip |

| Details[7] |

As the workpiece gets smaller, the precision also becomes finer. 2mm diameter Material: Copper, aluminum |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Formed Products M. PROTOTYPE, MODELING, 3D PRINTING Prototype Manufacturer N. PARTS PROCESSING TECHNOLOGY Plasticity Processing |