| Exhibitor name |

コダマコーポレーション株式会社

KODAMA Corporation, Ltd.

|

| Booth NO. |

4-362 |

| Address |

〒224-0032 神奈川県 横浜市都筑区茅ケ崎中央3-1 センター南SKYビル 4F

Center-minami SKY Bldg.4F 3-1 Chigasaki-chuo, Tsuzuki-ku, Yokohama, Kanagawa, JAPAN 224-0032

|

| Website |

https://www.kodamacorp.co.jp |

| Email |

|

| Phone number |

+81-45-949-1331 |

| The Main Item |

|

| Movie |

|

| Details[1] |

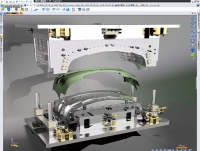

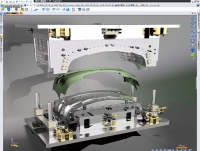

TopSolid'Mold is a plastic mold design support system that processes large data volumes, such as automotive bumper molds, at ultra-high speeds. It automatically detects parting lines on molded product models and easily creates parting surfaces.

The system supports 3D design of plastic molds with a rich library of mold bases and components, as well as powerful cooling circuit design functions. From the 3D model of the mold, it can instantly create 2D mold assembly drawings, part drawings, drill hole lists, and parts lists. These elements are constantly interlinked, helping to prevent errors and reduce design man-hours. |

| Details[2] |

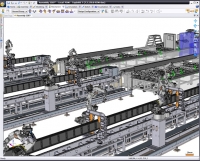

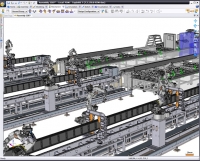

TopSolid'Design is a 3D design support system that integrates drafting, calculation, kinematic simulation, and realistic rendering into a single system. It enables ultra-fast processing for large-scale assemblies with tens of thousands of components, offers extensive surface modeling, powerful analysis, and a standard parts library with defined machining information. The system also supports drawing creation in compliance with JIS and ISO standards, ensuring high-quality design.

The integrated Product Data Management (PDM) system prevents assemblies from losing their references even if users change part names. |

| Details[3] |

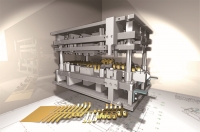

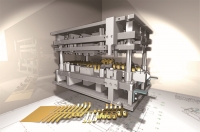

TopSolid'Progress is a press mold design support system that utilizes 3D CAD data of products to design single, progressive, and transfer molds. It performs all tasks in 3D, including blank development, blank layout design, strip layout design, and mold structure design. Part drawings and parts lists are automatically created from the 3D data. The product model, mold 3D model, and 2D mold assembly drawings and part drawings are interlinked, helping to prevent errors and reduce design man-hours.

Additionally, by integrating with the 3D solid CAD/CAM system TopSolid’Cam and the 3D wire-cut CAM system TopSolid'Wire 7, tool paths can be efficiently created. When design changes are made, the tool paths are automatically updated to reflect the changes, preventing rework and errors. |

| Details[4] |

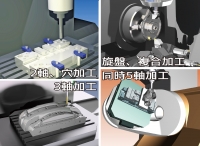

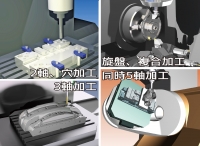

TopSolid'Cam is a 3D solid CAD/CAM system that covers everything from 2-axis and hole machining to turning, multi-tasking, and simultaneous 5-axis machining. It consolidates CAM systems that were previously scattered across different machine tools and machining methods. The integrated 3D CAD functionality supports the design of intermediate tolerance machining models and fixtures. The reliable and accurate machine simulation manages all machine movements, potential collisions, axis movements, and workpieces, minimizing the time spent on fine-tuning tool paths and ensuring safe machining. |

Category of

Exhibit Items |

L. CAD/CAM/CAE SYSTEM

CAD/CAM/CAE System

|