| Exhibitor name |

东莞嘉德制造科技有限公司

Dongguan Jiade Manufacturing Technology Co., Ltd.

|

| Booth NO. |

4-202 |

| Website |

www.dml-mould.com |

| Email |

|

| Phone number |

86-769-81718606 |

| PR message |

DML Mould offers tools and molding parts

We provide the below service

1) Mold & Part design

2) Plastic injection molding- with analysis for Cold & Hot Runner / Single & Multi-Cavity

3) Double-Color Mold

4) Overmolding

5) Prototype Tooling

6) 3D Printing

7) Insert Molds

8) Mass production

|

| The Main Item |

Injection Mould , Plastic&Rubber part molding |

| The name of Item[1] |

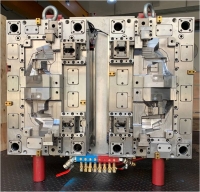

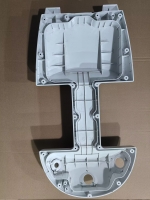

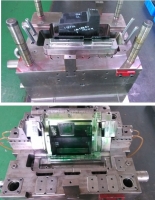

Injection Mold for Body Console |

| Details[1] |

Rich experience to design and manufacturing Automotive interior products, backed by a strong technical team for each component's technical requirements, problem prevention, and solutions

Provide the most comprehensive technical support and service for the customer's high demand plastic mold. Relying on the actual production and processing knowledge, optimize the design to meet the high quality development requirements of the product. Our team has rich development experience in Japan, USA and Europe automotive plastic mold , Agile conception plan ,High and stable quality to help customers provide design solution

|

| The name of Item[2] |

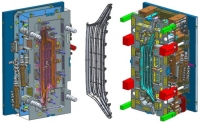

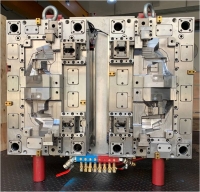

Injection Mould for Double Color Auto Part |

| Details[2] |

We have rich experience in designing and manufacturing double color rotating molds ranging from 150T to 1000T, as well as double color products for exterior and structural components.

Our products include double color molding components such as car throttle assemblies, seat side panels, wiper panels, and power tools |

| The name of Item[3] |

HIGH EFFICIECY ADVANCE CNC MACHINES |

| Details[3] |

High efficiency advance equipments imported from Japan Such as CNC OKUMA ,FANUC, EDM from SODICK. SEIBU wirecutting, These devices have the capabilities of high-speed cutting, high-precision positioning, and multi axis machining, and can handle various complex shapes and high-precision requirements of mold parts.

|

| The name of Item[4] |

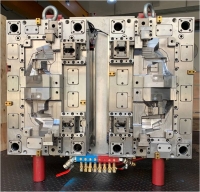

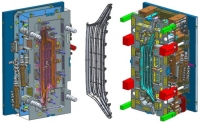

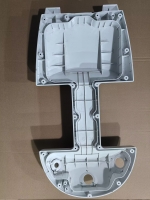

Injection mould for Auto Glove Box |

| Details[4] |

DML mould focus on producing high-precision injection molds for various industries (Mechanical, Household appliances, Medical equipment, Electronic equipment, Safety equipment, as well as Monitoring systems). We can do small and precise such as Mobilephone parts and as big as automotive parts. We have gained certificates of ISO 9001:2015, ISO 14000, and TS16949).

Advantage to Choose DML:

1. DML provide you customized mold from initial design to final production.Make concept to realism.

2. DML provide extensive custom molding solutions to meet your cost, efficiency and production requirements.

3. DML provide you with the products you need with high quality and favorable cost.

4. DML can also help further parts molding or assembling if needed.

|

| The name of Item[5] |

Mold Insert making |

| Details[5] |

Insert Manufacture

Optimized machine process, the fastest response, the highest quality requirements, to provide customers with urgently needed mold accessories.

Teams design and modify drawings or customer-supplied drawings according to customer requirements, use the best supplier resources to divide processes, run quickly, eliminate factory standby, process problems, high-demand testing requirements to provide customers with high-quality mold parts

|

| The name of Item[6] |

Plastic Molding for Street Lamp Industry |

| Details[6] |

Injection Machines from 80T-1300T, Meet the different needs of mold design and production. At the same time, the workshop focuses on improving production efficiency and controlling costs. By optimizing production processes, arranging production plans and equipment maintenance reasonably, efficient and stable production operations are achieved

|

| The name of Item[7] |

DML Injection Machines |

| Details[7] |

Injection Machines from 80T-1300T, Meet the different needs of mold design and production. At the same time, the workshop focuses on improving production efficiency and controlling costs. By optimizing production processes, arranging production plans and equipment maintenance reasonably, efficient and stable production operations are achieved

|

| The name of Item[8] |

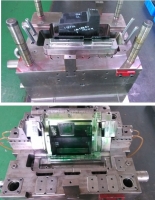

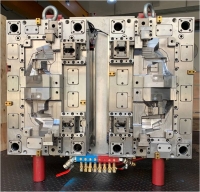

Injection Mould for Auto-Parts |

| Details[8] |

DML main products include: mobile phone accessories, electronic component, automotive accessories, medical products, military plastic supplies, digital, automotive, TV peripheral accessories, etc. Relying on a strong R&D team and advanced manufacturing equipment, as well as our own factory production system, we ensure that our products are of high quality, affordable, and highly competitive。

|

| The name of Item[9] |

Injection Mould |

| Details[9] |

Provide the most comprehensive technical support and service for the customer's high demand plastic mold. Relying on the actual production and processing knowledge, optimize the design to meet the high quality development requirements of the product. Our team has rich development experience in Japan, USA and Europe plastic mold , Agile conception plan ,High and stable quality to help customers provide design solution

|

| The name of Item[10] |

TESTING EQUIPMENT |

| Details[10] |

Advanced and high-precision testing equipment to accurately measure and analyze dimensional accuracy, tolerances, surface roughness, and hardness . The testing process strictly follows international and industry standards ,Strictly quality control starting from the raw material to the final testing of the mold finished product

|

Category of

Exhibit Items |

A. MOLDS, MOLD MATERIALS

Molds

Mold Components

Formed Products

|