株式会社スギノマシン

| Exhibitor name |

株式会社スギノマシン

SUGINO MACHINE LIMITED

|

|---|---|

| Booth NO. | 4-432 |

| Address |

〒936-8577 富山県 滑川市栗山2880番地 2880 Kuriyama, Namerikawa City, Toyama Prefecture, 936-8577, Japan |

| Website | https://www.sugino.com/ |

| Phone number | +81-90-1631-0156 |

| PR message | Sugino Machine consistently delivers surprises and excitement that surpass our customers’ expectations. We have six SUPER technologies, and we would like to introduce CWJP and CASF, our seventh SUPER technology. CWJP improves the lifespan of molds while CASF improves the surface roughness. |

| The Main Item |

|

| Movie |

|

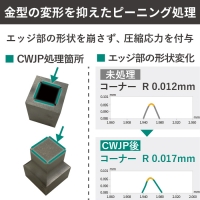

| The name of Item[1] | Cavitation Water Jet Peening(CWJP) |

| Details[1] |

This shotless processing method uses only water and does not use media, making it a clean processing method that does not require a washing process. It is possible to apply compressive residual stress without deforming edges and fine details and it is also possible to process deep and small holes, eliminating the cause of stress corrosion cracking inside a cooling circuit. This is the optimal processing method for improving fatigue strength of dies. |

| The name of Item[2] | Cavitation Abrasive Surface Finishing(CASF) |

| Details[2] |

Since surface treatment can reach curved internal holes such as flow channels, it is possible to improve the surface roughness of the flow channels in AM inserts. This technology also makes it possible to remove support material remaining in the part after metal additive manufacturing. Usually, support removal was performed by hand followed by a surface treatment polishing process, but with CASF both processes can be automated. |

| Category of Exhibit Items |

B. METAL MACHINE TOOLS Others F. SURFACE FINISHING, MODIFYING, WELDING Surface Finishing System Washing Machine Others N. PARTS PROCESSING TECHNOLOGY Others |