株式会社ファーステック

| Exhibitor name |

株式会社ファーステック

FIRSTEC CORPORATION

|

|---|---|

| Booth NO. | 5-153 |

| Address |

〒578-0911 大阪府 東大阪市中新開1-15-11 1-15-11, Nakashinkai, Higashi-Osaka, Osaka, 5780911 |

| Website | https://www.firstec.co.jp |

| Phone number | +81-72-960-3340 |

| PR message | Through our products, we propose productivity improvement and cost reduction to customers. The main exhibits are self-centering vises and zero-point systems for 5-axis machine tools, Mag Vises (Permanent Electromagnetic chucks) for cutting, EDM vises, indexing tables for EDM, and E3R system vises. |

| The Main Item |

|

| Movie |

|

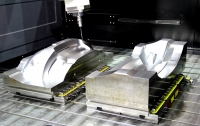

| The name of Item[1] | Self-centering Vise for 5-axis machine tools |

| Details[1] |

One side of the jaw swings 1.5° at one angle, enabling firm clamping of workpieces that are out of parallel. The jaws can be easily removed and quickly changed its direction or replaced with self-cut jaws. A special internal mechanism prevents workpiece lifting. Compatible with the zero-point system and interchangeable with zero-points systems of other companies. |

| The name of Item[2] | Zero-Point System for 5 axis machine tools |

| Details[2] |

We offer a variety of types to suit your application, including square type, round type, tomb stone type, pyramid type , raiser type, and flange types for scroll chucks. |

| The name of Item[3] | Mag Vise (Electro-Permanent Magnetic Chuck) |

| Details[3] |

Since clamping is performed only on the bottom surface of the workpiece, there are no clamps or other tools that interfere with the tool, dramatically increasing machining frexibility and eliminating the need to change the workpiece, thereby increasing machining efficiency and productivity. It is also suitable for simultaneous machining of multiple workpieces, increasing the number of workpieces that can be machined at one time, thereby increasing production per hour. The machine can also be automated, using magnets not only to clamp workpieces but also to transfer workpieces. |

| Category of Exhibit Items |

B. METAL MACHINE TOOLS Grinding Machine C. MACHINE ACCESSORY Work Holding Devices |