YAMAZAKI-MOLD CO., LTD. / JUNMENG MOULD CO., LTD

| Exhibitor name |

YAMAZAKI-MOLD CO., LTD. / JUNMENG MOULD CO., LTD

YAMAZAKI-MOLD CO., LTD. / JUNMENG MOULD CO., LTD

|

|---|---|

| Booth NO. | 4-311-3 |

| Address |

〒243-092 OVERSEAS(海外) No.379, Sec6, New Taipei Blvd., Taishan Dist., New Taipei City 243092, Taiwan (R.O.C.) No. 379, Sec. 6, New Taipei Blvd., Taishan Dist., New Taipei City 243092, Taiwan (R.O.C.) |

| Website | https://www.yamazaki-mold.com.tw |

| Phone number | 886-2-29080139 |

| PR message | Our company specializes in machining precision mold components, including motors, wire brackets, connectors, semiconductors, home appliances, and electronic machinery mold components. We also excel in the design and manufacturing of various stamping and plastic molds, as well as injection molding. |

| The Main Item |

|

| Movie |

|

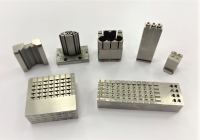

| The name of Item[1] | Mold Parts Processing (Grinding, EDM, Wire Cutting, Machining) |

| Details[1] |

・Technical discussions can be conducted in Japanese. ・We guarantee the quality to meet your requirements. ・We adhere strictly to the specified delivery dates. ・We can offer lower prices compared to manufacturing in Japan. ・We also support small-lot production of various types. Even with overseas orders, there is no need to worry about delivery times. Once we receive your order, we will start processing immediately, and the finished products can be delivered by air within 1-2 days, ensuring the same speed as domestic delivery in Japan! If you send us the drawings, materials, quantities, hardness, and other requirements via email, we will provide you with a quotation in the shortest possible time. |

| The name of Item[2] | Metal Parts Processing Services (Grinding, EDM, Wire Cutting, Machining) |

| Details[2] |

・Technical discussions can be conducted in Japanese. ・We guarantee the quality to meet your requirements. ・We adhere strictly to the specified delivery dates. ・We can offer lower prices compared to manufacturing in Japan. ・We also support small-lot production of various types. Even with overseas orders, there is no need to worry about delivery times. Once we receive your order, we will start processing immediately, and the finished products can be delivered by air within 1-2 days, ensuring the same speed as domestic delivery in Japan! If you send us the drawings, materials, quantities, hardness, and other requirements via email, we will provide you with a quotation in the shortest possible time. |

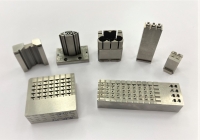

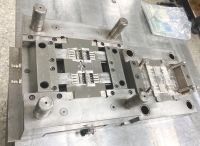

| The name of Item[3] | Injection Mold Design, Mold Manufacturing Requests (Made in Taiwan) |

| Details[3] |

We have Japanese engineers in our Osaka office, so you don't need to worry about discussions related to mold design and manufacturing. |

| The name of Item[4] | Precision Plastic Injection Services (Injection Machine Tonnages: 30t, 50t, 80t, 100t) |

| Details[4] |

In addition, we have a lineup of injection molding machines that can produce a wide variety of products ranging from 30 tons to 100 tons, allowing us to accommodate various sizes of products. |

| The name of Item[5] | Machinery Parts Processing, Aluminum Cutting Processing (Grinding, EDM, Wire Cutting, Machining) |

| Details[5] |

Our company is equipped with various processing equipment such as EDM, grinding, and wire cutting. We handle special precision parts processing requests for materials such as aluminum, copper, steel, stainless steel, iron, and resin, according to customer needs. ・Technical discussions can be conducted in Japanese. ・We guarantee the quality to meet your requirements. ・We adhere strictly to the specified delivery dates. ・We can offer lower prices compared to manufacturing in Japan. ・We also support small-lot production of various types. Even with overseas orders, there is no need to worry about delivery times. Once we receive your order, we will start processing immediately, and the finished products can be delivered by air within 1-2 days, ensuring the same speed as domestic delivery in Japan! |

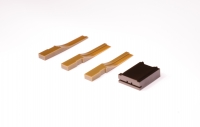

| The name of Item[6] | Tungsten Steel Mold Parts(Grinding, profile grinding, Wire Cutting, Electrical Discharge Machining) |

| Details[6] |

At our company, we employ the following advanced machining techniques to manufacture high-precision ultra-hard parts: Surface Grinding – Achieves high-precision surface finishing, providing a smooth and even surface. Profile Grinding – Precisely grinds complex shapes and fine contours, ensuring accurate and detailed processing. Wire Cutting – Enables intricate shaping and high-precision cutting, making it suitable for complex designs. Electrical Discharge Machining (EDM) – A non-contact machining method using electrodes, allowing for fine processing of high-hardness materials. If you are looking for high-precision processing of ultra-hard parts, please feel free to contact us. we are committed to meeting your needs! |

| The name of Item[7] | Motor Core Mold Design and Manufacturing |

| Details[7] |

|

| The name of Item[8] | Precision Oil Wire Cutting Processing |

| Details[8] |

|

| The name of Item[9] | Precision Machining of Ceramic Materials |

| Details[9] |

|

| The name of Item[10] | Motor Core Production |

| Details[10] |

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Materials Mold Components N. PARTS PROCESSING TECHNOLOGY Cutting Processing Plasticity Processing Grinding Processing Plastic Processing Precision Processing |