SHENZHEN JK Plastic Mold Co.,LTD.

| Exhibitor name |

SHENZHEN JK Plastic Mold Co.,LTD.

SHENZHEN JK Plastic Mold Co.,LTD.

|

|---|---|

| Booth NO. | 4-415 |

| Website | www.jkmold.com |

| Phone number | +86 13530335758 |

| PR message | Established in 2004, JK specializes in mold design, fabrication, and molding, primarily for the automotive industry. With a skilled engineering team, strict quality control, and advanced precision equipment, we provide high-quality molds and services. |

| The Main Item |

|

| The name of Item[1] | 3-Color Injection Molded A/B Pillar Trim |

| Details[1] |

This product is a 3-color injection molded A/B pillar trim for a global luxury automotive brand, made from PMMA, ABS, and TPE materials. The trim enhances vehicle sealing, reducing wind noise and water penetration, improving comfort and safety. The PMMA offers high transparency, ABS provides surface gloss, and TPE improves flexibility and durability. The mold is designed with 1st injection of PMMA, 2nd injection of ABS, and 3rd injection of TPE. The injection is achieved through the main injection machine, TOP side, and non-operating side. The mold features motor-driven and guide rail systems for secondary molding rotation. This structure allows the mold to be used on a standard injection machine with two additional injection stations, eliminating the need for special 3-color injection machines, reducing costs and equipment investment. |

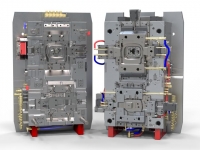

| The name of Item[2] | Dual-material automotive fuel tank cap mold |

| Details[2] |

The sequential injection of PP and TPE allows the mold to combine the rigidity of PP with the flexibility of TPE, resulting in a durable, high-performance automotive part. The tunnel slider and core-pulling system are essential for achieving deep and complex features in the fuel tank cap, demonstrating advanced engineering. Quality control throughout the manufacturing process ensures that every part meets strict industry standards. |

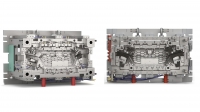

| The name of Item[3] | Automotive Air Intake Grille Mold |

| Details[3] |

The cooling system is optimized for efficient cooling, reducing deformation and warping, enabling stable, high-quality mass production. The mold surface is finely polished to achieve a smooth, glossy finish, enhancing the grille's aesthetic appeal. This mold combines durability, efficiency, and precision, meeting strict automotive industry standards for producing high-quality, durable, and visually appealing air intake grilles. |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Materials Mold Components |