日進工具株式会社

| Exhibitor name |

日進工具株式会社

NS TOOL CO., LTD.

|

|---|---|

| Booth NO. | 5-143 |

| Address |

〒140-0014 東京都 品川区大井1-28-1 住友不動産大井町駅前ビル6F 6F Sumitomofudosan-ooimachiekimae Bldg.,1-28-1,Oi,Shinagawa-ku,Tokyo 140-0014 Japan |

| Website | https://www.ns-tool.com |

| Phone number | +81-3-6423-1191 |

| PR message | A wide product range of small diameter end mills for precision and micro machining. At the same time, collected a lot of work samples and products that can solve customers’ concern regarding precision and micro machining. |

| The Main Item |

|

| Movie |

|

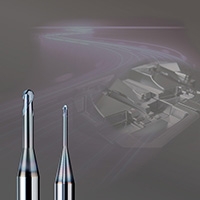

| The name of Item[1] | [[[ NEW ]]] MPX Coating Long Neck Ball End Mill for 420 Hardened Stainless Steels [XRBH230] |

| Details[1] |

|

| The name of Item[2] | CBN End Mill [CBN CORE LINE] |

| Details[2] |

|

| The name of Item[3] | PCD End Mill [PCD CORE LINE] |

| Details[3] |

To achieve nano-level surface finish, we developed many technical elements such as special cutting edge, production method, and know-how for machining. It is possible to achieve [smooth and shiny] machined surfaces on various materials from hardened steel to cemented carbide. |

| The name of Item[4] | MUGEN COATING PREMIUM High Efficiency Lens Form 3-Flute End Mill |

| Details[4] |

Conventionally, the ball R is 1/2 of the outer diameter, however this product is designed so that the bottom edge R is greater than the outer diameter, and the cusp height is the same. In some cases, the pick feed can be set lager. Additionally, the 3-flute design increases the feed rate, resulting in improved machining efficiency. Combine MUGEN COATING PREMIUM, which is suitable for direct milling on hardened steels, and provides long life and stable machining accuracy from pre-hardened steel to hardened steel of about 65HRC. |

| The name of Item[5] | Series with a cutter diameter of 0.01 mm or larger [MICRO EGDE] |

| Details[5] |

|

| The name of Item[6] | Long Neck End Mill for Copper Electrode |

| Details[6] |

DLC Coating optimized for copper and copper alloy machining increases tool life compare to conventional tool. |

| Category of Exhibit Items |

D. CUTTING TOOLS Cemented Carbide Tools Others |