株式会社J・3D

| Exhibitor name |

株式会社J・3D

J.3D

|

|---|---|

| Booth NO. | 4-121-8 |

| Address |

〒455-0815 愛知県 名古屋市港区油屋町1丁目30番地 1-30 Aburaya-cho, Minato-ku, Nagoya, Aichi. |

| Website | https://j3d.co.jp |

| Phone number | +81 52-389-1901 |

| PR message | We will introduce examples using metal and resin 3D modeling samples. We will introduce examples of mold parts with improved cooling effects using 3D cooling water pipes. We will provide examples of moldless prototyping of products, as well as proposals for weight reduction and integration. |

| The Main Item |

|

| Movie |

|

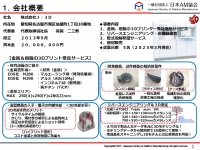

| The name of Item[1] | 3D cooling water pipes using metal 3D modeling |

| Details[1] |

By freely arranging cooling channels in areas that cannot be processed with conventional methods or where problems occur in the product, and by innovatively improving the cooling effect, we dramatically increase the production efficiency of resin molding and aluminum die-casting molds, and greatly reduce the rate of product defects In addition, by greatly improving the cooling effect, we dramatically improve the life of the mold, suppress galling of molded products and residual material residue during mass production, and dramatically reduce the frequency of mold stoppages Although the production of parts using metal 3D modeling is expensive, we propose reducing the cost of part production by proposing hybrid modeling We provide all the know-how we have cultivated through our track record and experience of producing over 1,500 mold parts using metal 3D modeling |

| The name of Item[2] | Various modeling services using metal 3D modeling |

| Details[2] |

We will propose ways to utilize 3D modeling, various construction methods, and design know-how that suit your needs. We will propose equipment introduction, manufacturer and model selection, operational considerations, know-how, and use cases. We will introduce examples of prototypes and developed parts that use shapes that cannot be reproduced using conventional construction methods, as well as aluminum, special steel, titanium alloys, heat-resistant steel, and stainless steel alloys. We will propose know-how for utilizing AM, which will likely be applied in all industries in the future. |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Mold Components M. PROTOTYPE, MODELING, 3D PRINTING Prototype Manufacturer Service Bureau N. PARTS PROCESSING TECHNOLOGY Cutting Processing |