株式会社関東製作所

| Exhibitor name |

株式会社関東製作所

KANTO MFG.CORP.

|

|---|---|

| Booth NO. | 4-541-30 |

| Address |

〒452-0821 愛知県 名古屋市西区上小田井2-116 5-18-13, Morishita, Kotoku, Tokyo 1350004, Japan |

| Website | https://kanto-seisakusyo.jp/ |

| Phone number | +81-52-325-6380 |

| PR message | Kanto Seisakusho Co., Ltd. offers a wide range of services, including mold manufacturing (injection and blow molding), mass production, prototyping, and small-lot production, automated machine production (machining, assembly, and inspection equipment), and development support. |

| The Main Item |

|

| Movie |

|

| The name of Item[1] | Mass Production of Resin Products |

| Details[1] |

In terms of quality control, We have owned coordinate measuring machines, inspecting machines of both contact and non-contact types. We have been ISO 9001 certified. We have completed the manufacture line covering from mold tooling design/ manufacture to mass production both in Fukuoka and Hamamatsu Factory. In each factory there are maintenance systems of mold tooling, so we can redesign and repair products anywhere to save the shipping cost and time. Since we deployed the dedicated department of manufacturing “Automatic machines,” we can manufacture various kinds of machines including the visual inspection machines to assure the quality control, welding machines and pressure test machines for tanks. |

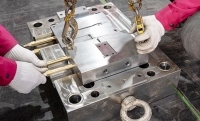

| The name of Item[2] | 【Injection Mold Tooling 】Capable of handling injection molding machine size 1,800t mold. |

| Details[2] |

We propose the most appropriate shape by using flow analysis software. Also as a mold manufacturer, we propose selection of suitable steels and specification according to quantity and materials. We have an ideal environment in all our branches including machining center. We enable bowl-shaped metal processing with several 5-axis processors, which reduces EDM(Electric Discharge Machine). We have many experiences to manufacture front grills and meter panels of automobile. So we are confident in mold toolings with decorations which requires high technique like resin plating, piano black painting. Regarding polish, we can finish products as finely as grit number #3000. |

| The name of Item[3] | Trial Models, Small-batch Production, Supplies |

| Details[3] |

In factory we set up mold tooling manufacture area next to mold machines so that we implement a continuous cycle of molding trial and tooling adjustment. In the case of trial models and mold by small-batch without mold toolings, we handle almost all methods such as 3D printer, cutting, vacuum casting, FRP etc. We undertake the service of molding trial, trial models, 3D measurement and then provide quantified finish accuracy to the customer. We visualize the customer’s image and lead to the final products. Our engineers catch the customer’s image after lots of meetings and lead to 3D data creation. In this way, we create appropriate products exactly the way customers demand. Even in the case you have only an original product, we can manufacture trial models, small-batch products and supplies, using reverse engineering method. |

| The name of Item[4] | 【Automatic machine】 PROPOSAL FOR AUTOMATIC EQUIPMENT |

| Details[4] |

Automatic processing machines automatically perform post-processes after blow molding, such as deburring, cutting, drilling, and cutting, as well as route-out (hollowing out) and gate cutting of injection molded products. We provide integrated in-house services from design of machinery and equipment to electrical control. Wiring and sequence programming are also performed by in-house staff. Program adjustments, such as changing the order of operations, can be completed on the spot according to customer needs. We have experience in controlling robot cylinders, servo motors, etc. in-house. |

| The name of Item[5] | 【Development Support】 |

| Details[5] |

The production of products using new materials such as bio-based materials and waste plastic materials is flexible and has a great deal of unknown potential. In fact, we have collaborated with designers from other industries to produce desks and chairs that utilize bio-based materials and waste plastic. In this way, Kanto Seisakusho will continue to pioneer the development of products that utilize bio- and waste-plastic materials, based on our "responsibility" as a company that handles plastic materials. |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds P. ROBOT, AUTOMATION Robot, Automation |