株式会社アルモニコス

| Exhibitor name |

株式会社アルモニコス

Armonicos Co., Ltd.

|

|---|---|

| Booth NO. | 5-361-2 |

| Address |

〒430-7721 静岡県 浜松市中央区板屋町111-2 浜松アクトタワー21階 Act Tower 21F, 111-2 Itaya-machi, Nakaku, Hamamatsu, Shizuoka, 430-7721 JAPAN |

| Website | http://www.armonicos.co.jp |

| solution@armonicos.co.jp | |

| Phone number | +81-53-459-1000 |

| PR message | Since its establishment in 1984, Almonikos has been solving various problems faced by manufacturers, Since its establishment in 1984, Almonikos has solved a variety of problems faced by manufacturers by combining the know-how of its customers with Almonikos' core competence, 3D shape processing. |

| The Main Item |

|

| Movie |

|

| The name of Item[1] | spGate |

| Details[1] |

|

| The name of Item[2] | spGauge |

| Details[2] |

spGauge is an inspection software that uses point cloud data measured by a 3D scanner and design data. It is used in the production preparation stage of the manufacturing industry, as well as in the prototype and mass production stages. Alignment that achieves the desired results The most important function for comparing point cloud data and CAD data is “alignment. To obtain reliable inspection results, it is necessary to precisely align the point cloud data of the area to be inspected. In addition to point cloud data and CAD data, it is also possible to align the point cloud data of the master product with the point cloud data of the object to be measured. Based on the experience and techniques accumulated in the field of manufacturing, spGauge can perform optimal alignment for each inspection purpose. |

| The name of Item[3] | spScan |

| Details[3] |

It is easy to control the surface to be created according to your purpose, such as “reproducing a faithful shape on a surface with minimal errors from the point cloud” or “creating a smooth surface with few control points. Created surfaces can be output in general-purpose CAD formats (IGES, STEP) for use in CAD/CAM/CAE. Surface data created by reversing a solid shape can also be used as solid data in CAD systems. Partial Reverse Function Greatly Reduces Reverse Man-hours Does it take a lot of time to reverse from a point cloud? If you have CAD data, you can compare the point cloud data with the CAD data, and then recreate the surface of only the error part. Since only the error part needs to be reversed, the man-hours required can be significantly reduced compared to reversing the entire surface. |

| The name of Item[4] | ClassNK-PEERLESS |

| Details[4] |

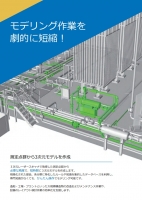

ClassNK-PEERLESS” software creates 3D models required for design and construction in a short time from point cloud data acquired with a 3D laser scanner. ClassNK-PEERLESS is highly evaluated for its intuitive operability that simplifies modeling, and is used in the fields of ships, plants, factory equipment, and building equipment. >Usability that reduces man-hours by 70%. >Automatic creation of piping, steel, etc. >Easy measurement and simulation |

| The name of Item[5] | T-Promotion |

| Details[5] |

T-Promotion was developed in response to the press industry's request to efficiently determine the thickness of panels that have actually been formed! T-Promotion is a system that uses polygon data (non-contact measurement data) from the front and back sides of a press panel to evaluate the percentage increase or decrease in thickness relative to a standard thickness dimension. This system is effective for detecting thickness reductions and bottlenecks. |

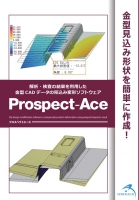

| The name of Item[6] | Prospect-Ace |

| Details[6] |

Prospect-Ace is a 3D software that significantly reduces the man-hours required to create prospective surfaces by using a function for creating prospective surfaces for each failure phenomenon and a batch deformation function using an analytical prospective mesh. >Significantly reduces the man-hours required to create prospective surfaces Prospect-Ace” deforms CAD surfaces according to each failure situation. Utilizing simulation technology, non-contact measurement data, and know-how accumulated in the mold manufacturing field, Prospect-Ace can create a prospective mold shape CAD in a short time, significantly shortening the mold manufacturing period. >Unparalleled Operability & Low Cost The simple, prospective deformation function for each failure phenomenon realizes unparalleled ease of use. The elimination of unnecessary functions has realized a low price of 500,000 yen (excluding tax) for an annual license. |

| The name of Item[7] | AE-Deform |

| Details[7] |

|

| The name of Item[8] | Sakura3D SCAN |

| Details[8] |

Sakura3D SCAN is an application that converts objects into 3D data using devices equipped with LiDAR scanners, such as Apple's iPad Pro and iPhone Pro series. Until now, acquiring 3D data required the use of expensive CMMs. However, from now on, using the Sakura3D SCAN application, 3D data can be acquired “alone,” “easily,” and “inexpensively” using an inexpensive iPad or iPhone. >License Subscription (1 week, 1 month, 1 year) >Price Application download: free of charge Scanning and preview display: Free One data output per day: Free of charge Weekly subscription (unlimited output): ¥200 (tax included) Monthly subscription (unlimited output): ¥600 (tax included) Annual subscription (unlimited output): ¥5,000 (tax included) |

| The name of Item[9] | Contracted development of dedicated systems and solutions |

| Details[9] |

We will propose the best approach for you. Why don't you solve your problems with Almonikos' contract development? What is contract development? We develop tailor-made systems and software to suit each customer's business needs, We develop tailor-made systems and software to suit each customer's business needs. >Consulting ability based on our long years of experience. We can consult with you even if you do not have a specific solution to your problem! We can find the best solution from a wide variety of options! >Specialists in handling 3D data Able to process 3D data in a short period of time and with high quality! We can handle difficult geometry processing and expand the options for what can be achieved with the system! >Constantly updated with new technology! We can differentiate ourselves from our competitors by incorporating cutting-edge technology into our development! |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Mold Components Formed Products K. PRECISION MEASURING, OPTICAL MEASURING MACHINES & INSTRUMENTS Measuring Machines and Instruments 3D Coordinate Measuring Machines & Instruments L. CAD/CAM/CAE SYSTEM CAD/CAM/CAE System N. PARTS PROCESSING TECHNOLOGY Measuring Machine P. ROBOT, AUTOMATION IoT, AI |