JT SPACE株式会社

| Exhibitor name |

JT SPACE株式会社

JT SPACE Co., Ltd.

|

|---|---|

| Booth NO. | 2-111 |

| Address |

〒108-0073 東京都 港区三田一丁目2番18号 TTDビル TTD Bldg,1-2-18,Mita,Minatoku,Tokyo,108-0073 Japan |

| Website | https://www.jtspace.co.jp/ |

| Phone number | 07092874870 |

| The name of Item[1] | Liquid Cooling Heat Exchanger |

| Details[1] |

Conventional Methods: Three-dimensional special structures were not possible. Additive Manufacturing: Additive manufacturing enables the realization of integrated special three-dimensional structures, improving conversion efficiency by designing them in conjunction with flow paths. Size:190(L)× 82 (W)× 40 (H)mm³ |

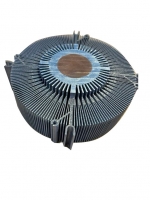

| The name of Item[2] | Heat Sink with cooling fins |

| Details[2] |

Conventional Methods: Three-dimensional special structures were not possible. Additive Manufacturing: Additive manufacturing enables the realization of integrated special three-dimensional structures, improving conversion efficiency by designing them in conjunction with flow paths. Size:88 (L) × 88 (W) × 35 (H) mm³ |

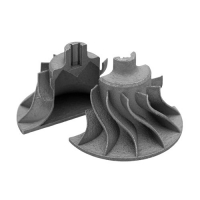

| The name of Item[3] | Cutaway Light-Weight Impeller (Lattice) |

| Details[3] |

Conventional Methods: Precision casting or shaping by multi-axis processing of round bars, which cannot be hollowed to achieve weight reduction. Additive Manufacturing: Allows the production of hollow or embedded structural products, reducing product weight and inertia moments, effectively enhancing performance, and reducing energy consumption. Size: 100 (L) × 100 (W) × 67 (H) mm³ |

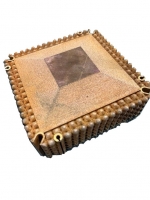

| The name of Item[4] | Structurally-optimized honeycomb light-weight structure |

| Details[4] |

Conventional Methods: Normally, structures are lightened by drilling or hollowing out, but this method increases grooves and complicates shapes, leading to increased processing time and costs, and sometimes making processing impossible. Additive Manufacturing: Enables weight reduction through complex shapes and three-dimensional intersecting designs. Size: 160 (L) × 60 (W) × 18 (H) mm³ |

| The name of Item[5] | Heat Sink with Cooling Fins (Copper) |

| Details[5] |

Conventional Methods:Three-dimensional special structures were not possible. Additive Manufacturing: Additive manufacturing enables the realization of integrated special three-dimensional structures, improving conversion efficiency by designing them in conjunction with flow paths. Size: 88 (L) × 88 (W) × 35 (H) mm³ |

| The name of Item[6] | Special Structure (Copper) |

| Details[6] |

Conventional method: Cannot achieve special three-dimensional structures. Layered manufacturing: Can achieve integrated special three-dimensional structures. By designing the flow path and combining it with the polyhedral structure, the conversion efficiency can be improved. Size: 80(L) × 80(W) × 100(H) mm³ |

| The name of Item[7] | Hinge Cover |

| Details[7] |

The products exhibited this time are smartphone hinge covers with 800 shafts. Size: 300(L) × 300(W) × 240(H) mm³ |

| Category of Exhibit Items |

M. PROTOTYPE, MODELING, 3D PRINTING Metal 3D Additive Manufacturing |