株式会社スギノマシン

| Exhibitor name |

株式会社スギノマシン

SUGINO MACHINE LIMITED

|

|---|---|

| Booth NO. | 6A-255 |

| Address |

〒936-8577 富山県 滑川市栗山2880番地 2880 Kuriyama, Namerikawa City, Toyama Prefecture, 936-8577, Japan |

| Website | https://www.sugino.com/ |

| Phone number | +81-90-1637-2388 |

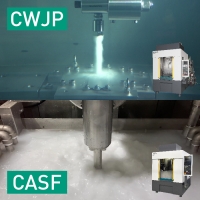

| PR message | Exhibited shotless peening technology "CWJP" using high-pressure water. This environmentally and cost friendly method improves fatigue strength and life of molds. The "CASF" post-processing technology for AM parts allows surface smoothing treatment and support material removal in a single pass. |

| The Main Item |

|

| Movie |

|

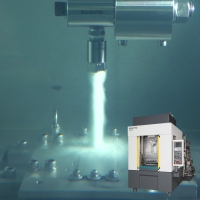

| The name of Item[1] | CWJP (Cavitation Water Jet Peening) |

| Details[1] |

Cavitation is generated by water jetting at high speed from a special cavitation (bubble) accelerating nozzle into the water. When this cavitation collapses near the workpiece, the impact force in the GPa (gigapascal) class produces a peening effect. Shotless peening, which uses only water, is a clean process that generates no industrial waste. Also, no media is used, so there is no need for cleaning or polishing in the post-processing steps. This also reduces the risk of contamination. Cavitation (air bubbles) for peening are extremely small, Peening can be performed on any parts or areas. CWJP can peen fine areas where media could not penetrate in the past. Translated with DeepL.com (free version) |

| The name of Item[2] | CASF (Cavitation Abrasive Surface Finishing) |

| Details[2] |

CASF can perform smoothing treatment up to approximately 200 μm from the surface. Abnormal layers and unmelted metal powder are removed, and at the same time, compressive stress is applied, which improves the fatigue strength of the part. Because a fluid is used, uniform surface treatment can be applied to down-skin sections and curved internal boreholes such as flowpipes. In addition, CASF can be used to remove support structures that remain on the workpiece after additive manufacturing. In the past, removal was often done manually, and after removal, the surface of the part had to be polished. With CASF, the removal of support structures and smoothing of the part surface can be done in a single pass. |

| Category of Exhibit Items |

F. SURFACE FINISHING, MODIFYING, WELDING Surface Finishing System Die & Mold Mending System |