中辻金型工業.株式会社

| Exhibitor name |

中辻金型工業.株式会社

Nakatsuji Kanagata Kogyo Co.,LTD

|

|---|---|

| Booth NO. | 1-121-86 |

| Address |

〒577-0016 大阪府 東大阪市長田西4丁目1-16 4-1-16 Nagatanishi, Higashiosaka-city,OSAKA,Japan |

| Website | http://www.nkk-24.co.jp/ |

| Phone number | +81-6-6746-0056 |

| PR message | While the company was founded on the strength of tinplate drawing dies, we offer hybrid dies of thin-plate and thick-plate technologies by working on thick-plate and drawing products for automobile parts and agricultural equipment parts. |

| The Main Item |

|

| The name of Item[1] | Cutting sample |

| Details[1] |

Direct processing on hardened material Processed without roughening Processing time 70 min. |

| The name of Item[2] | Direct tapping |

| Details[2] |

Direct tapping for high hardness materials Tapping can be performed on materials with hardness up to HRC60 without pre-hole drilling. Can also be used for stop holes, with the smallest diameter starting from M3. |

| The name of Item[3] | Thick plate drawing products |

| Details[3] |

This is a thick plate drawing product. It is drawn from a 5mm-thick material and the tip is curled. |

| The name of Item[4] | bracket |

| Details[4] |

Automobile parts Manufactured by progressive die Parts requiring 3-point mating |

| The name of Item[5] | Large press dies for thin plates |

| Details[5] |

Manufactured by progressive die. Although the product and mold are large compared to the plate thickness, We guarantee strict accuracy. |

| The name of Item[6] | Dissimilar materials/space welding |

| Details[6] |

It is made by pressing and welding dissimilar materials. Material: STKM and SUS304 Thickness: 3.0 We use technology to join dissimilar materials such as iron and SUS. The welded part is welded with a gap of 2 mm. |

| The name of Item[7] | N-CUT Ultra Copper Solid Square End Mill 4 Flutes NK40 Series |

| Details[7] |

Hardness is achieved by using UMGCarbide as base metal. Heat resistance is 1000℃, surface altitude MAX 3800Hv. The coated surface is very hard and has excellent heat resistance and high sliding properties. |

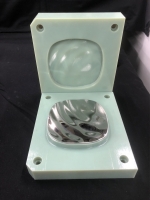

| The name of Item[8] | DIGITAL MOLD PRESS |

| Details[8] |

Scratch-less Pressing on mirror surface material Digital mold press Mirror surface material of SUS304 is formed by a 3D printer (digital mold) formed by a 3D printer. This molding process leaves no scratches on the product. No scratches are left on the product, realizing an unprecedented molding process. The molding process is unprecedented. |

| The name of Item[9] | automotive parts |

| Details[9] |

Progressive die 200t press Precision parts with matching mating parts |

| The name of Item[10] | Forming of thick high-tensile materials |

| Details[10] |

Material: SPH590 Thickness: 10.0 Thick plate forging press 4mm thickening process |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Components D. CUTTING TOOLS Cemented Carbide Tools |