株式会社 富士精工

| Exhibitor name |

株式会社 富士精工

FujiSeiko Co., Ltd.

|

|---|---|

| Booth NO. | 1-402 |

| Address |

〒379-2301 群馬県 太田市藪塚町2991-1 2991-1, Yabuzuka-cho, Ota-shi, Gunma, 379-2301 |

| Website | http://www.fuji-gr.co.jp/ |

| Phone number | +81-277-78-5566 |

| PR message | We can offer the One Stop Service for plastic injection mold manufacturing including mold design, machining, finishing, assembly and molding trial. We also offer die-cast and thixomold molds too. We will introduce the Heat & Cool molding technology and the appearance measures of GF-containing resin. |

| The Main Item |

|

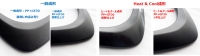

| The name of Item[1] | Control panel with Piano Black molding |

| Details[1] |

Conventional molding product: Specular gloss cannot be obtained because the ultra-specular state cannot be completely transferred to the molded product. Molding with Heat & Cool technology: The mirror surface can be faithfully reproduced on the molded product. A glossy ultra-specular gloss is achieved, weld lines are not visible. Also the flow marks and other molding defects can be eliminated. |

| The name of Item[2] | Direct decoration milling: Faithfully directly milling the design according to the 3D model by MC. |

| Details[2] |

Conventional molding: The texture cannot be faithfully reproduced on the molded product. Molding with H&C technology: The texture can be faithfully reproduced on the molded product, and 100% of the same decoration processing can be repeated for any number of molds. |

| The name of Item[3] | Direct decoration milling: Faithfully directly milling the hair line according to the data by MC. |

| Details[3] |

Conventional molding : Fine hair lines cannot be completely transferred to the molding product, and texture cannot be obtained. Molding with H&C technology: A high-quality hairline with a matte feel can be faithfully reproduced on the molding product. |

| The name of Item[4] | Molding with resin containing GF: Improve the glass exposure on the surface of the molded product. |

| Details[4] |

In common sense, GF is exposed on the surface of the molding product, and it cannot be used as a part that people touch. General molding: The glass floats on the molding product, so it cannot be used for parts that people touch. Molding with H&C technology: The glass floating on the surface of the molding product has been greatly improved, and it can be used without any effect even if a person grips it. |

| The name of Item[5] | Molded product with clear resin containing clear glass filler. |

| Details[5] |

In order to realize a transparent molding product by combining clear GF with clear resin, the material developed by the material manufacturer is realized as a transparent molding product as intended by the material manufacturer using Heat&Cool molding technology. We have been confirmed that a transparent molded product can be molded. Result with this molding product, we believe that new applications for this material will be opened. |

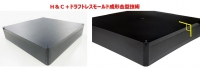

| The name of Item[6] | Heat & Cool technology with Draft-free molding technology. |

| Details[6] |

|

| The name of Item[7] | 3-color molding: The unique structure of the 3-color mold has realized automatic gate cut process. |

| Details[7] |

In addition, acrylic lenses molded in other processes were assembled with two-color molded products. Therefore, we propose new manufacturing technology. With our technology, we are now able to obtain molded products that incorporate acrylic lenses using a dedicated three-color mold and molding machine. |

| The name of Item[8] | Heat & Cool with Metallic molding without black line |

| Details[8] |

We have developed heat and cool molding technology in an ultra-high temperature range and special molds. And we realized a unique control in the mold to eliminate the orientation of metallic resin molding. |

| The name of Item[9] | Heat & Cool with In Mold press molding |

| Details[9] |

This molded product is similar to the result of the injection press method on a dedicated molding machine. However, this technology does not require a special molding machine and can be molded with a general molding machine. Molding with H&C only: Surface distortion occurs in thick 5mm and uneven 3mm area. H&C+ Mold Press: Improves surface distortion. |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Formed Products N. PARTS PROCESSING TECHNOLOGY Precision Processing |