石崎プレス工業株式会社

| Exhibitor name |

石崎プレス工業株式会社

ISHIZAKI PRESS INDUSTRIAL CO., LTD.

|

|---|---|

| Booth NO. | 2-411 |

| Address |

〒664-0842 兵庫県 伊丹市森本1-98-2 1-98-2 Morimoto Itami Hyogo, 664-0842 |

| Website | www.ispress.co.jp |

| Phone number | +81727826715 |

| PR message | We are a precision stamping company, mainly engaged in deep drawing of thin materials. We respond to advanced technological needs with high product realisation & mass production capabilities by designing dies make use of simulation and high-precision dies using various high-precision machine tools. |

| The Main Item |

|

| The name of Item[1] | Elliptical deep drawing of ultra-thin stainless steel |

| Details[1] |

|

| The name of Item[2] | Deep drawing in austenitic stainless steel using non-chlorine oil |

| Details[2] |

|

| The name of Item[3] | Multifunctional processing (Drawing + Forging) |

| Details[3] |

Generally, the aperture is entirely radius shaped, but by applying forging know-how, it is formed with an extremely small radius and taper. The flange also satisfies the strict flatness requirements |

| The name of Item[4] | Examples of various drawing processes |

| Details[4] |

High-precision die machining enables high-precision forming of corner radii whose dimensions are difficult to control. |

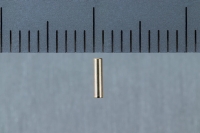

| The name of Item[5] | Ultra-small drawing process |

| Details[5] |

|

| The name of Item[6] | Plate forging |

| Details[6] |

|

| The name of Item[7] | Reverse drawing |

| Details[7] |

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Components N. PARTS PROCESSING TECHNOLOGY Cutting Processing Plasticity Processing Grinding Processing Precision Processing |