三和クリエーション株式会社

| Exhibitor name |

三和クリエーション株式会社

SANWA CREATION Co.,Ltd.

|

|---|---|

| Booth NO. | 1-101-40 |

| Address |

〒211-0051 神奈川県 川崎市中原区宮内1-26-8 1-26-8 Miyauchi, Nakahara Ward, Kawasaki, Kanagawa, Japan |

| Website | http://www.sanwa-creation.co.jp/ |

| Phone number | +81-44-740-6800 |

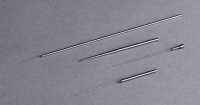

| The name of Item[1] | ultra-small pin gauge |

| Details[1] |

This is a single unit type in which the pin section from the shaft to the tip is finished by machining alone. This ultra-high precision product has the smallest diameter in the industry for a pin gauge made with ultra-hard materials (super alloys, zirconia ceramic). It is possible to issue a calibration certificate and a traceability system diagram as needed. If you make a requires for your required measurement standards or precision level, we will provide you with an estimate. Please feel free to consult with us. |

| The name of Item[2] | Pin gauges |

| Details[2] |

The ultra-precision class can be used as a master pin gauge. It is possible to make them to the desired size ranging from φ0.1 mm to 10 mm for the outer diameter (φD), and from 40 to 60 mm in overall length. “Calibration certification” and “traceability system diagrams” can be issued as necessary (a separate fee is required). If we receive your desired measurements or precision, we will calculate an estimate. Please feel free to consult with us. |

| The name of Item[3] | Centerless / cylinder processed products |

| Details[3] |

We can respond to a wide range of needs, ranging from small lot manufacturing to mass production. Cemented carbide,Ceramic,SKH,SUS,Diamond,CFRP,Carbon,Silicon, Pure titanium,Nickel titanium,Silicon carbide,Silicon nitride,etc. |

| The name of Item[4] | Needle pin |

| Details[4] |

|

| The name of Item[5] | Non-round and eccentric pins |

| Details[5] |

We can meet needs for a variety of eccentric shapes, such as ellipses, squares, and everything from triangles to multi angle shapes. In addition to being used for core pins of molds and pilot pins for pressing dies, the triangle type can be used as a reamer. Also, we can manufacture punches that have eccentricity from the shank to the tip for the purpose of effective use of the space in the interior of dies through the miniaturization of dies. |

| The name of Item[6] | Punch pin |

| Details[6] |

They also find applications in the production of precision holes in the heads of ink jet printers, the production of carrier tape used to transport semiconductors and electronic components, the stainless production of connector parts, and more. Also, it is possible to reduce damage to the punch and extend its operating life by using PCD (artificial polycrystal diamond) for the material of the tip in ultra-thin press processing such as for copper foil and aluminum foil. |

| The name of Item[7] | Pilot pin |

| Details[7] |

In a case where these products are to be used in dies and equipment which are required to be highly corrosion resistant and nonmagnetic, we propose the use of zirconia ceramics. |

| The name of Item[8] | Core pin |

| Details[8] |

In addition to being used in molds that make resin components for medical care and semiconductors, they are also used to process the head components of ink jet printers. For core pins that are used amidst a work environment which involves resins being heated to high temperatures when forming in a mold, we can manufacture the pins using highly heat resistant zirconia ceramics. |

| The name of Item[9] | Electrical discharge machining use copper electrode |

| Details[9] |

It has a past track record of manufacturing tough pitch copper, copper tungsten, and other materials. We can attach not only round bar electrodes, but also long tapers and R shapes. This product is manufactured by grinding, meaning it has the advantage of being able to process small-diameter electrodes with less run out inaccuracies when compared to electrodes that have been manufactured by lathe processing. |

| The name of Item[10] | Die |

| Details[10] |

The measurement data for a sample with an inside diameter of φ4xa depth of 20 mm is a roundness degree of 0.08 μm, and a degree of cylindricity of 0.82 µm. |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Mold Components N. PARTS PROCESSING TECHNOLOGY Grinding Processing Precision Processing Measuring Machine |