黒田精工株式会社

| Exhibitor name |

黒田精工株式会社

KURODA PRECISION INDUSTRIES LTD.

|

|---|---|

| Booth NO. | 3-301-71 |

| Address |

〒212-8560 神奈川県 川崎市幸区堀川町580-16 川崎テックセンター Kawasaki Tech Center, 5th floor, 580-16Horikawa-cho, Saiwai-ku, Kawasaki,Kanagawa, 212-8560, Japan |

| Website | https://www.kuroda-precision.co.jp |

| Phone number | 81-44-555-3159 |

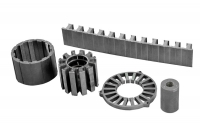

| PR message | FASTEC SYSTEM is our proprietary press tool system which enables simultaneous blanking and assembly of steel sheet lamination in the die. We are the only company in the world that can provide three types of lamination methods: interlocking lamination, laser welding lamination and glue lamination. |

| The Main Item |

|

| The name of Item[1] | High Efficiency Glue Lamination Core |

| Details[1] |

|

| The name of Item[2] | Laser Welding Lamination Core |

| Details[2] |

|

| The name of Item[3] | Interlocking Lamination Core (HEV Main Motor Core) |

| Details[3] |

|

| The name of Item[4] | Epoxy Resin Fixation Technology |

| Details[4] |

By quantitative management, resin filling volume in a magnet hole is stable. So it can lead good rotation balance. By low pressure molding, lower strain is placed on core. And the higher radiation performance leads low loss. |

| The name of Item[5] | Interlocking Lamination Core (Other In-Car Motor Core) |

| Details[5] |

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Formed Products |