ハイマージャパン株式会社

| Exhibitor name |

ハイマージャパン株式会社

Haimer Japan K.K.

|

|---|---|

| Booth NO. | 3-321 |

| Address |

〒530-0037 大阪府 大阪市北区松ケ枝町1-39 東天満エンビイビル 1F Higashi-Tenma Envy Building, 1-39, Matsugae-cho, Kita-ku, Osaka-city, Japan |

| Website | www.haimer.jp |

| Phone number | +81-6-4792-7980 |

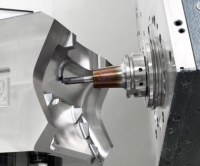

| PR message | The HAIMER Group - the world market leader in tool shrinking and balancing technology. We will present a wide variety of products from tool holders and presetters, shrinking and balancing technology to solid carbide end mills and 3D sensors. |

| The Main Item |

|

| The name of Item[1] | Power Clamp |

| Details[1] |

|

| The name of Item[2] | Modular Balancing System[Tool Dynamic] |

| Details[2] |

As tooling is a rotating body, balance is crucial. Spindle speeds on modern machine tools have continuously increased over the last few years, resulting in higher cutting volumes and profits. The increase in speed has also increased the demand for tools and holders. This is because the effects of unbalance are more pronounced at higher spindle speeds. This results in vibration, surface finish degradation and shorter tool life. Only by precisely balancing the tool and toolholder can the machine's capacity with regard to speed, cutting volume and surface finish be optimised. This is because balancing reduces vibration. Spindle and tool wear is reduced, downtime is reduced and machining safety is increased. |

| The name of Item[3] | Tool Preseter「Microset Automatic Drive」 |

| Details[3] |

The UNO series combined with the auto-focus and automatic measuring functionality ensures maximum efficiency in tool measurement. You can also select the optimum specification to suit your requirements. |

| The name of Item[4] | Endmill Moduler System [Duo-Lock™] |

| Details[4] |

Duo-Lock™ technology presents the problem of the increasing cost of carbide by offering a modular interface for cutting tool heads Duo-Lock™ offers maximum stability due to its double cone-bonded thread design. The result is unrivalled precision and productivity, and the coupling is virtually unrivalled in the most demanding applications. |

| The name of Item[5] | Shrink Fit Chuck |

| Details[5] |

|

| Category of Exhibit Items |

C. MACHINE ACCESSORY Tool Holders Accessories & Attachments D. CUTTING TOOLS Cemented Carbide Tools K. PRECISION MEASURING, OPTICAL MEASURING MACHINES & INSTRUMENTS Measuring Machines and Instruments N. PARTS PROCESSING TECHNOLOGY Grinding Processing Measuring Machine P. ROBOT, AUTOMATION Robot, Automation |