Formlabs株式会社

| Exhibitor name |

Formlabs株式会社

Formlabs Inc.

|

|---|---|

| Booth NO. | 3-612 |

| Address |

〒140-0001 東京都 品川区北品川3-6-9 北品川369ビル 1F Kitashinagawa 369 Building 1F 369 Kitashinagawa, Shinagawa-ku, Tokyo, 140-0001 |

| Website | https://formlabs.com/jp/ |

| Phone number | +81-6-6718-4004 |

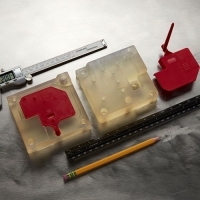

| PR message | Exhibiting Products: 3D printers Product Names: Form 3+, Form 3L (SLA) & Fuse 1 (SLS) Overview: Formlabs' patented LFS Technology enable high resolution and precise 3D printing which can be used as molds for various molding. We offer Rapid Tooling with our intuitive and affordable desktop 3D printers. |

| The Main Item |

|

| The name of Item[1] | Desktop SLA 3D Printer: Form 3+ |

| Details[1] |

The SLA method uses a laser that produces the highest precision and smoothest surface quality of any other 3D printing technologies, and our patented Low Force Stereolithography (LFS)™ technology further improves precision and surface quality. The product is also compatible with mold production for plastic injection molding, vacuum molding, metal sheet molding, and thermoforming. The 3D printing process allows for immediate molding after mold design, and completion within a few hours or the next morning. Design adjustments after prototyping and re-prototyping can be carried out on the same day, and a rapid iterative verification cycle can be established to realize "rapid tooling," a method of shortening development time and reducing costs that has become mainstream in recent years, speeding up your product development process and creating time for quality improvement. Formlabs - the affordable, intuitive, easy-to-use 3D printer is within reach. |

| The name of Item[2] | Large Format Desktop SLA 3D Printer: Form 3L |

| Details[2] |

The SLA method uses a laser that produces the highest precision and smoothest surface quality among any other 3D printing technologies, and our patented Low Force Stereolithography (LFS)™ technology further improves precision and surface quality. The Form 3L is the best printer for mold productions for plastic injection molding, vacuum molding, metal sheet molding, and thermoforming especially when you need larger molds or need to produce many smaller molds at once. The 3D printing process allows for immediate molding after mold design, and completion within a few hours or the next morning. Design adjustments after prototyping and re-prototyping can be carried out on the same day, and a rapid iterative verification cycle can be established to realize "rapid tooling," a method of shortening development time and reducing costs that has become mainstream in recent years, speeding up your product development process. |

| The name of Item[3] | 3D Printing Material: Rigid 10K Resin |

| Details[3] |

Rigid, Strong, Industrial-Grade Prototypes This highly glass-filled resin is the stiffest material in our engineering portfolio. Choose Rigid 10K Resin for precise industrial parts that need to withstand significant load without bending. Rigid 10K Resin exhibits a smooth matte finish and is highly resistant to heat and chemicals. |

| The name of Item[4] | 3D Printing Material: High Temp Resin |

| Details[4] |

Temperature Resistant Molds Consider High Temp Resin when clamping and injection pressures are not too high and Rigid 10K Resin cannot meet the required injection temperatures. High Temp Resin offers a heat deflection temperature (HDT) of 238 °C @ 0.45 MPa, the highest among Formlabs resins. |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Components Formed Products B. METAL MACHINE TOOLS Special Purpose Machines M. PROTOTYPE, MODELING, 3D PRINTING Prototype Manufacturer Service Bureau Resin Molding Machine RP Machine Others N. PARTS PROCESSING TECHNOLOGY Plastic Processing Precision Processing |