オーエスジー株式会社

| Exhibitor name |

オーエスジー株式会社

OSG Corporation

|

|---|---|

| Booth NO. | 5-113 |

| Address |

〒442-8543 愛知県 豊川市本野ケ原三丁目22番地 3-22 Honnogahara, Toyokawa-City, Aichi 442-8543, Japan |

| Website | https://www.osg.co.jp |

| Phone number | +81-533-82-1111 |

| PR message | OSG has always strived to create high value-added products to meet the evolving needs of the manufacturing industry. OSG offers A Brand products to accommodate a wide spectrum of applications and materials, such as high-hardness steel and non-ferrous metals, as well as micro and precision machining. |

| The Main Item |

|

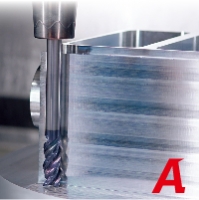

| The name of Item[1] | AE-TS-N, AE-TL-N, AE-VTS-N & AE-VTFE-N DLC Coated Carbide End Mills for Non-ferrous Materials |

| Details[1] |

In addition to the standard type end mill, this series includes a high-performance type that supports various machining with high efficiency and high quality. Highly efficient and highly accurate deep side milling at L/D of 5 or more is made possible by the 2.5 x D length of cut configuration with large step milling of up to 2 x D. Furthermore, a sharp corner edge type has been newly added to the lineup for effective milling of straight corners. With a spectrum of styles and sizes, the DLC coated end mill series is designed to support a wide range of applications, from part processing to the crafting of aircraft components. |

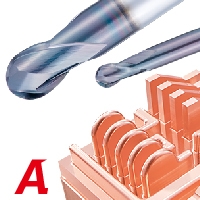

| The name of Item[2] | AE-MSS-H, AE-MS-H, AE-ML-H, AE-BM-H, AE-BD-H & AE-LNBD-H Carbide End Mills for High-hardness Steels |

| Details[2] |

The multi-flute square type and radius type lineup includes the AE-MSS-H stub end mill, AE-MS-H short end mill and AE-ML-H long end mill. The AE-H series features unequal spacing teeth to suppress chattering and optimum cutting edge specifications to enable stable machining. The AE-H series also includes three ball type end mills, the 4-flute high-efficiency AE-BM-H for roughing and semi-finishing, the 2-flute AE-BD-H and 2-flute long neck AE-LNBD-H for high-precision finishing. |

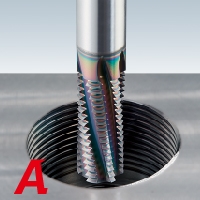

| The name of Item[3] | AE-VMSS, AE-VMS, AE-VML & AE-VMFE Anti-vibration Carbide End Mills |

| Details[3] |

|

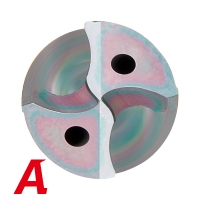

| The name of Item[4] | AE-LNBD-N DLC Coated 2-flute Carbide Ball End Mill for High Precision Finishing in Copper Electrodes |

| Details[4] |

|

| The name of Item[5] | Highly Efficiency Multi-purpose Tap Series |

| Details[5] |

■ A-SFT Spiral Tap 1. Sharp cutting edge stabilizes chip shape. 2. Variable lead flute enables trouble-free chip evacuation. These key features enable the A-SFT to excel in a wide range of materials and machining equipment – from manual drilling machines to the latest advanced machining centers. ■ A-TPT & A-S-TPT Tapered Pipe Taps Taper threading is a process that is prone to chip trouble. The A-TPT and A-S-TPT are engineered with a long overall length and flute to facilitate trouble-free chip evacuation. Furthermore, the thread section adopts an overlapping geometry, with staggered cutting edges to ensure appropriate depth of cut to prevent galling. A-POT point tap for through-holes and XPF X performer forming tap that does not generate cutting chips are also available to accommodate various machining needs. |

| The name of Item[6] | AT-1, AT-2& AT-2 R-SPEC Thread Mills |

| Details[6] |

Advantages 1. Less restrictions on cutting conditions than taps 2. Stable threading Disadvantages 1. Deflection 2. Requires multiple passes and zero cuts 3. Long processing time The following products are engineered to resolve the above disadvantages. ■ AT-1 1-pass Thread Mill 1. Left-hand helix geometry to prevent deflection 2. Unequal spacing and variable lead flute to suppress chattering 3. EgiAs coating for high wear resistance ■ AT-2 (DUROREY coating for high hardness steels) and AT-2 R-SPEC (DLC-IGUSS coating for non-ferrous metals) Enable helical drilling and threading simultaneously. 1. Special cutting edge shape suppresses bending of the tool 2. Left-hand cut configuration enables climb milling to prolong tool life 3. Roughing teeth are added to distribute the load |

| The name of Item[7] | ADO Coolant-through Carbide Drills |

| Details[7] |

The ADO series adopts a unique R gash geometry (PAT. in Japan) that breaks chips into compact pieces with excellent evacuation capability. Furthermore, by using a wavy point form and low web thickness, low thrust resistance and stable torque are achieved, allowing overwhelming stability and high-efficiency drilling. The 40 x D and 50 x D types have adopted a highly rigid 25 ° helix flute with smooth chip evacuation and high tool rigidity qualities ideal for ultra-deep-hole applications. |

| The name of Item[8] | PDZ, PMD & PZAG Counterboring Indexable Tools |

| Details[8] |

■ PDZ Indexable Flat Drill The PDZ uses a muscle breaker insert with excellent chip breaking capability. It is compatible with a wider range of applications. ■ PMD Multi-function Cutter The PMD supports a wide range of applications with a single tool. It uses two types of inserts to enable continuous cutting. For the drilling and plunging edge, the PMD uses the same muscle breaker insert as the PDZ with excellent chip breakability. ■ PZAG Counterboring Cutter The PZAG is a counterboring cutter with perfect chip control. The PZAG also uses the same muscle breaker insert as the PDZ and PMD. |

| The name of Item[9] | “Regrind & Recoat” to Rejuvenate Used Tools to Like-new Condition |

| Details[9] |

Last but not least, OSG has collaborated with Nihon Hard Metal to promote the recycling of carbide tools that can no longer be reground. OSG actively implements initiatives relating to energy conservation, waste reduction, prevention of pollution, and material recycling in various processes throughout the OSG Group to contribute to a healthy planet and society. |

| Category of Exhibit Items |

D. CUTTING TOOLS Cemented Carbide Tools Cemented Carbide Tips Diamond Tools Others |