協栄プリント技研株式会社

| Exhibitor name |

協栄プリント技研株式会社

KYOEI PRINT GIKEN CO.,LTD.

|

|---|---|

| Booth NO. | A-104-39 |

| Address |

〒182-0025 東京都 調布市多摩川1-21-1 1-21-1 Tamagawa, Chofu City, Tokyo Pref., 182-0025, Japan |

| Website | https://www.kpg.jp/ |

| Phone number | +81-42-484-2151 |

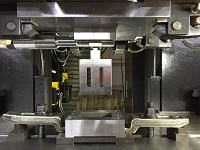

| PR message | We are a mold maker focusing on the design and manufacture of press dies. We will exhibit precision press dies that punch out various materials, blade dies that do not require a backing plate, dies for vent holes in plastic resin containers, and the production control system KPG IoT Solution. |

| The Main Item |

|

| The name of Item[1] | Steam vent processing mold for plastic resin containers |

| Details[1] |

|

| The name of Item[2] | Blade type that does not require a backing plate |

| Details[2] |

|

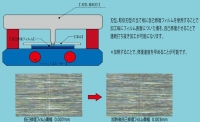

| The name of Item[3] | Blade type that can be continuously punched using a self-healing film |

| Details[3] |

A carrier sheet may be used instead of the backing plate, but since the carrier sheet is attached to the entire sheet material for processing, the work man-hours increase and the material cost increases significantly. By using a self-healing film for the backing plate of the blade type and engraving blade type, the scratches on the film surface can be self-repaired at each processing, enabling continuous punching. |

| The name of Item[4] | Production management system KPG IoT Solution |

| Details[4] |

|

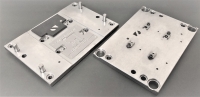

| The name of Item[5] | Simple punch punching die FQDC that can be used from the 90,000 yen level |

| Details[5] |

The merits of introducing FQDC are (1) shipping within the next day at the longest, (2)high cost merit because it is excellent in profitability even in small-quantity production, (3)easy handling method and no technology required, depending on the handling operator. There are no unstable elements of quality, (4) Both the upper and lower molds are lightweight at about 1 kg, so even women can easily carry them. (5) The compact mold makes it possible to effectively utilize the jigs and tools storage space. , And so on. |

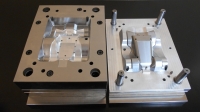

| The name of Item[6] | Three-dimensional shape mold |

| Details[6] |

|

| The name of Item[7] | Clock parts |

| Details[7] |

|

| The name of Item[8] | Production management system KPG IoT Solution |

| Details[8] |

By visualizing the value of the factory, it contributes to productivity improvement and cost reduction. |

| The name of Item[9] | Cemented Carbide Engraving Blade Type |

| Details[9] |

The petals of the cherry blossoms are made of cemented carbide and serve as blades. The tip of the blade is extremely sharp and is in the area of microfabrication. Advanced technology is required to achieve this with cemented carbide. |

| The name of Item[10] | Ultrasonic vibration press die |

| Details[10] |

By combining ultrasonic vibration and servo press motion, unprecedented press processing has become possible. |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Components L. CAD/CAM/CAE SYSTEM Production Control System N. PARTS PROCESSING TECHNOLOGY Cutting Processing Precision Processing |