日進工具株式会社

| Exhibitor name |

日進工具株式会社

NS TOOL CO.,LTD

|

|---|---|

| Booth NO. | A-244 |

| Address |

〒140-0014 東京都 品川区大井1-28-1 住友不動産大井町駅前ビル6F 6F Sumitomofudosan-ooimachiekimae Bldg.,1-28-1,Oi,Shinagawa-ku,Tokyo 140-0014 Japan |

| Website | https://www.ns-tool.com |

| Phone number | +81-3-6423-1191 |

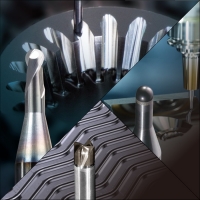

| PR message | Introduction of high precision and micro end mill and cutting technology. Suggesting variety of end mills such as high precision end mill for 70HRC hardened steel 「MRBSH230SF」, realizes high quality finishing performance 「CBN series」, and achieves mirror surface after finishing process 「PCD series」. |

| The Main Item |

●CBN END MILL 「CBN CORE LINE」 ●PCD END MILL 「PCD CORE LINE」 |

| The name of Item[1] | MUGEN COATING PREMIUM Plus 2-Flute Long Neck End Mill for Hardened Steel and High accuracy cutting |

| Details[1] |

Advanced cutting edge design and new material, combining new developed coating improves the tool life compared to convention products. (1) New coating「MUGEN COATING PREMIUM Plus」is optimized for hardened steel from 60HRC to 70HRC. (2) Adopting sharp cutting edge with reduced cutting load and new material with fracture resistance. (3)PATENT pending new tool design realized high precision R accuracy that is ±0.003mm. (4)The shank length is optimized to support the shrink fit chuck enables machining in a high rigid condition. (5)High accuracy precision shank with a tolerance range of 2 μm shank supported shrink fit chuck. Line up from R0.05~R3, total 83 sizes can satisfy varieties of cutting shape. |

| The name of Item[2] | CBN END MILL 「CBN CORE LINE」 |

| Details[2] |

In order to stabilize machining accuracy, it is important to control tool wear. In the finishing process that the machining time is longer than the roughing process, the dimensional accuracy and surface roughness varies as the tool wear progresses, making it impossible to obtain stable machining accuracy. To solve this problem, NS TOOL has developed tools that use cBN (cubic boron nitride) material, which is harder than coated solid carbide tools, to fulfill the needs of our customers. NS TOOL suggested “CBN Core Line” that provides a total of 14 series and 508 sizes to satisfy a variety of machining shapes, realizes high efficiency, high precision, and stable machining of a long time finishing on hardened steel. |

| The name of Item[3] | PCD END MILL 「PCD CORE LINE」 |

| Details[3] |

In recent years, there has been a growing demand for higher functionality in automotive safety technology and smartphone fields, which has led to demands for higher precision and higher accuracy in the components. As a result, the molds used for mass production of these parts are becoming harder and more precise in order to increase durability. As a proposal for high precision machining, NS TOOL offers direct milling for mirror surface finishing on high hard steels using PCD end mills. The tool material, PCD (polycrystalline diamond sintered body), minimizes tool shape change due to tool wear and achieves nano-level surface finishing on hardened steel and cemented carbide. “PCD Core Line” has a lineup of 28 sizes with 3 items and realizes mirror surface looks "smooth, even and shiny" finished surface through cutting. |

| Category of Exhibit Items |

D. CUTTING TOOLS Cemented Carbide Tools Diamond Tools |