EXHIBITOR SEARCH

コダマコーポレーション株式会社

| Exhibitor name |

コダマコーポレーション株式会社

Kodama Corporation, Ltd.

|

|---|---|

| Booth NO. | 3-231 |

| Address |

〒224-0032 神奈川県 横浜市都筑区茅ケ崎中央3-1 センター南SKYビル 4F Center-minami SKY Bldg.4F 3-1 Chigasaki-chuo, Tsuzuki-ku, Yokohama, Kanagawa, JAPAN |

| Website | http://www.kodamacorp.co.jp |

| Phone number | +81-45-949-1331 |

| FAX | +81-45-949-1515 |

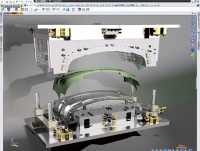

| PR message | TopSolid offers powerful, industry-specific solutions for designing products and producing tools for mold making and cutting tool production. As all TopSolid modules are completely integrated from design through simulation and manufacturing, the perfect numeric chain is created for toolmaking. |

| The Main Item |

TopSolid’Mold

|

| The name of Item[1] | TopSolid'Mold 7 |

| Details[1] | TopSolid’Mold speeds up the design of core cavity blocks •Global or differential control of shrinkage factors •Rapid analysis of drafts and back drafts of plastic parts •Automatic detection of parting lines •Assisted creation of parting surfaces TopSolid’Mold adapts to your working methods •Preliminary study mode for quick quotes •Incorporation of changes to parts in the design process •Management of multiple core cavity blocks and versioned molds TopSolid’Mold helps you define all moving parts •Library of mold bases (standard or custom) •Installation of the standard components required to define the movement (slides, pins, etc.) •Automatic adjustment of components to respect the defined path TopSolid’Mold for optimal creation of cooling circuits •Creation of cooling circuits on 3D sketch •Circuit views •Automatic positioning of cooling components TopSolid'Mold quickly produces drafts for moldmakers •Injection / Ejection views, local cutaways •Automatic dimensioning of drilled holes

|

| The name of Item[2] | TopSolid'Design 7 |

| Details[2] | With TopSolid, users can change the name of a part at any time, without having to worry about losing the reference in the assemblies that use it. Parts and assemblies undergoing modifications are made known to all, thanks to the vault option. You can work in offline mode by reserving parts and assemblies for modification, and then reassembling them, without being disrupted by another simultaneous modification.

|

| The name of Item[3] | TopSolid'Cam 7 |

| Details[3] | The global CAD/CAM solution for milling, lathing, MillTurn and erosion •A simple, intuitive, global and scalable CAD/CAM solution that can be adapted to the needs of every company •Complete integration with the TopSolid range for CAD/CAM for the machining, sheet metal and wood industries •A uniquely user-friendly and innovative interface •Protect your know-how in the long term with TopSolid's methods An expert in every market segment: from simple to high added-value parts •Extra-fast generation of paths by strategy propagation •With TopSolid'Cam, controlling a lathe/grinder or a continuous 5-axis machining center is easy and consistent •Preview of choices, reliable and accurate simulations that manage all the inter-operation movements, possible collisions, the travel of each axis and management of residual material all contribute to minimizing the time spent fine-tuning The ideal tool for production engineering •Integrated with a powerful CAD associated with machining

|

| The name of Item[4] | TopSolid'Progress |

| Details[4] | TopSolid’Progress helps you prepare your engineering projects Standard and native interfaces: IGES, STEP, DXF / DWG, CATIA, PTC, Parasolid, SAT Data clean-up and repair Conversion into sheet metal, identification of folds, loss management Unfolding / unstamping (Forming Technology Incorporated technology) Nesting, material engagement Strip creation by specific operation: cutting, folding, deformation, shearing

|

| Category of Exhibit Items |

L. CAD/CAM/CAE SYSTEM CAD/CAM/CAE System |