EXHIBITOR SEARCH

株式会社長峰製作所

| Exhibitor name |

株式会社長峰製作所

NAGAMINE MANUFACTURING CO.,LTD

|

|---|---|

| Booth NO. | B-121-78 |

| Address |

〒766-0026 香川県 仲多度郡まんのう町岸上1725-26 1725-26, kishinoue,Manno-cho, Nakatado-gun, Kagawa, Japan |

| Website | http://www.nagamine-manu.co.jp |

| Phone number | +81-877-75-0007 |

| PR message | We are providing ceramic honeycomb catalyst and ceramic injection molding parts using our mold and die technology. We will exhibit extrusion die for honeycomb structure, the ultrafine ceramic honeycomb structure of world's smallest class, and ceramic molding parts using fused deposition modeling. We are looking forward to you visit our booth. |

| The Main Item |

|

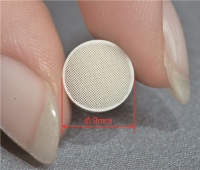

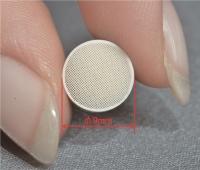

| The name of Item[1] | Micro ceramic honeycomb |

| Details[1] |

|

| The name of Item[2] | Extrusion die for molding honeycomb structure |

| Details[2] | Extrusion die for molding honeycomb structure. The minimum slit width is 0.07 mm and the cell density is 1200 cells/inch^2. In addition to square lattices, hexagonal lattices and deformed lattices can be constructed. |

| The name of Item[3] | Ceramic injection molding |

| Details[3] |

|

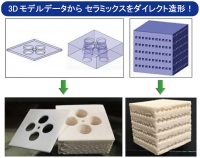

| The name of Item[4] | 3D ceramic modeling |

| Details[4] |

|

| The name of Item[5] | Conductive Ceramics/Piezoelectric Ceramics |

| Details[5] | We have various ceramic materials as follows. Piezoelectric ceramics (PZT), conductive zirconia/alumina ceramics, visible light shielding ceramics, etc. We can produce fine parts of each material using our injection molding technology. |

| The name of Item[6] | Metal porous body |

| Details[6] |

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Formed Products M. PROTOTYPE, MODELING, 3D PRINTING Prototype Manufacturer Service Bureau N. PARTS PROCESSING TECHNOLOGY Cutting Processing Grinding Processing Precision Processing |