EXHIBITOR SEARCH

株式会社チバダイス

| Exhibitor name |

株式会社チバダイス

ChibaDies Co.,Ltd.

|

|---|---|

| Booth NO. | B-121-10 |

| Address |

〒340-0834 埼玉県 八潮市大曽根414 414, Osone, Yashio-shi, Saitama, Japan |

| Website | http://chibadies.co.jp/ |

| Phone number | +81-48-997-6621 |

| PR message | As a specialized manufacturer “Can consult a gear”, we will introduce molds, molded gears, metal gears, noise and durability tests. Particularly PEEK’s “thick teeth worm wheel” and metal “thin tooth worm” realize miniaturization of reduction gears. We propose a consistent solution from design to prototype, mold, mass production and testing. |

| The Main Item |

|

| The name of Item[1] | Rolling Worm |

| Details[1] |

–Uses Door lock actuators, sunroof motors, power window motors, etc. –Materials Brass, steel, others |

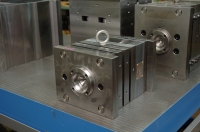

| The name of Item[2] | Gear Cavities |

| Details[2] |

–Uses Plastic gear molds, dies for diecast gears, dies for pressed gears, dies for forged gears, broaches, dies for sintered gears, etc. –Types Spur gears, helical gears, racks, bevel gears, face gears, crown gears, worms, worm wheels, cam gears, internal gears, non-circular gears, ratchets, sprockets, timing pulleys, etc. –Profiles Involute, cycloid, clock, special and other profiles. –Size of teeth 2.0 module and below –Materials Pre-hardened steel (HRc35°-45°) Hot forming steel (HRc50°-60°) Other –Style With bottom and penetrating types |

| The name of Item[3] | Gear Molds |

| Details[3] |

–Types of Dies Plastic gear molds Dies for diecast gears Dies for pressed gears Dies for forged gears Broaches –Uses Automobiles, robots, cameras, office automation and audio-visual equipment, home electronics, clocks, micromachines, etc. –Profiles Involute, cycloid, clock and special profiles –Types of Plastic Gears Worms, worm wheels, helical gears, spur gears, bevel gears, face gears, crown gears, racks, cam gears, internal gears, non-circular gears, ratchets, sprockets, splines, timing pulleys, knurling parts, serrations, screws, etc. |

| The name of Item[4] | Hourglass Worm Wheel |

| Details[4] |

Helical gears had been used with worm wheels due to manufacturing difficulties. By making them into hourglass shapes, the surfaces contact resulting in improved durability. We can also form a single integral molding with flanges on either side of the gear. |

| The name of Item[5] | Plastic Gear |

| Details[5] |

|

| The name of Item[6] | Metal Gears |

| Details[6] |

Machining of metal bevel gears Die Cast Gear A molten alloy is injected into the gear die to make gears with high precision casting surfaces. Sintered Gear Metal powder is compression molded within the die and sintered. Pressed Gear Plates and rods are pressed to form precision gears. |

| The name of Item[7] | CD processing gear |

| Details[7] |

Brass rods, phosphor bronze rods, nickel silver rods, aluminum rods and other free-machining nonferrous metal materials Free-machining steel, free-machining stainless steel and other steel materials Duracon, nylon, ABS and other engineering plastic rods –Machining Range [CD Gear Rod] Involute, cycloid and special: M0.04-M1.5 f2.5-f45 Helical gears: Up to 40 degree torsion angle [CD Knurling Rod] Longitudinal knurling rod, Chiballet (double-cut), special shaped rods: p0.1-p5.0 f0.4-f50 [CD Deformed Rods] Deformed rods made from straight rods, square rods and round rods –Precision CD Parts Gears, timing pulleys, handles, keys, knobs, insert parts, sliding parts, axle bearings, bushings, wheels –Uses Cameras, surveying equipment and other optical products, Electrical machinery, Automobiles Other precision parts CD machining rods have high dimensional accuracy for their entire length and allow for higher precision parts after cutting and other secondary fabrication. |

| The name of Item[8] | Inspection and Testing |

| Details[8] |

|

| The name of Item[9] | Trial gear |

| Details[9] |

Also High-speed prototyping of injection molded articles from dozens of pieces "Speed Try" is also suitable for repeat molding, making it ideal for small volume production. |

| The name of Item[10] | CF-2 and CF-3 Model Deflection Inspection Devices |

| Details[10] |

With many precision parts that have been created through a variety of methods such as molding, pressing or cutting, the devices can be used by inserting the spindle into the part. Such measurements can be peformed in no time. Much thought has been put into these simple deflection inspection devices, so they can be used easily for various types of inspection and are convenient for use anywhere. Diameter (maximum) of spindles and pin gauges that can be used f8mm(CF-2), f17mm(CF-3) Deflection inspection range of measurement (maximum) f60mm(CF-2), f100mm(CF-3) Range of measurement (maximum) for surface runout f100mm(CF-2) |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Components Formed Products K. PRECISION MEASURING, OPTICAL MEASURING MACHINES & INSTRUMENTS Measuring Machines and Instruments N. PARTS PROCESSING TECHNOLOGY Plastic Processing Precision Processing Others |