EXHIBITOR SEARCH

株式会社山本金属製作所

| Exhibitor name |

株式会社山本金属製作所

YAMAMOTO METAL TECHNOS CO., LTD.

|

|---|---|

| Booth NO. | B-711 |

| Address |

〒547-0034 大阪府 大阪市平野区背戸口2-4-7 2-4-7, Setoguchi, Hirano-ku, Osaka-city, Osaka, 547-0034 |

| Website | https://yama-kin.co.jp/index.html |

| Phone number | +81-6-6704-1800 |

| FAX | +81-6-6704-6582 |

| PR message | Our company operates in the manufacturing industry based on the two core technologies: Precise cutting technology and Measuring evaluation technology. Especially in measuring evaluation area, we have a service (Modified Internal Residual Stress) to measure Residual Stress of a material. Then, we are producing our own machines. |

| The Main Item |

|

| The name of Item[1] | MIRS®【Modified Internal Residual Stress】 |

| Details[1] |

Furthermore, we have experience in measuring shapes varying from metallic sheet to tube. *Applicable plate thickness: 4mm~200mm *Applicable weight: up to 10 tons |

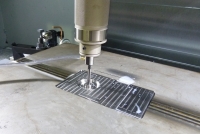

| The name of Item[2] | MULTI INTELLIGENCE® Cutting version |

| Details[2] |

|

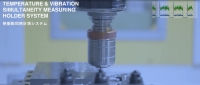

| The name of Item[3] | MULTI INTELLIGENCE® FSW version |

| Details[3] |

With specific statistics, MULTI INTELLIGENCE(R) helps 'VISUALIZE' the abrasion of the FSW tool, the temperature of the joining point, probe shoulder as well as surface temperature, then we shall be able to determine the spindle load, to observe defects after welding (if any). As a result, the optimum welding condition shall be found out. |

| The name of Item[4] | GIGA QUAD® |

| Details[4] |

Each spindle is driven by an electric motor via a V belt and the numberof revolution is counted by photo-sensor. Thus, this machine can performfatigue tests for 4 specimens simultaneously. |

| Details[6] |

|

| Category of Exhibit Items |

B. METAL MACHINE TOOLS Turning Machines Miscellaneous Machine Tools C. MACHINE ACCESSORY Hydraulic & Pneumatic Machines & Apparatus M. PROTOTYPE, MODELING, 3D PRINTING Resin Molding Machine Metal Molding Machine N. PARTS PROCESSING TECHNOLOGY Cutting Processing |