ABOUT THE SHOW

Exhibitor Search

Exhibitor Detail

| Exhibitor name |

キャムタス株式会社

CAMTUS INC.

|

|---|---|

| Booth NO. | 6B-312 |

| Address |

〒663-8244 兵庫県 西宮市津門綾羽町4-11 4-11 TsutoAyaha-cho,Nishinomiya,Hyogo 663-8244 JAPAN |

| Website | http://www.camtus.co.jp |

| info@camtus.co.jp | |

| Phone number | +81-798-37-0580 |

| FAX | +81-798-37-0680 |

| PR message | Camtus Inc. offers in-house development CAD/CAM systems, pursuing the true value of made in Japan. Our system is available from 2D CAD, Multitask machining through 5X Machining. Rich functions for users' needs. |

| The Main Item |

3D CAD/CAM Speedy mill Next

|

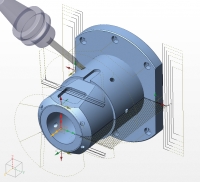

| The name of Item[1] | 3D CAD/CAM Speedy mill Next |

| Details[1] | Based on 2D-CAD, we realize the intuitive operation by direct modeling, equipping with features of designing parametric (Constraints and History). As for CAM, the essential features are fully equipped: Hole milling, Contour pocket milling, and Face milling, etc. Simultaneous 3/5 axes machining for curved surfaces are available as well. These are all adapted to Multi-face milling and Multi-task machining. Furthermore, we offer rich features for designing press dies, that is, “Dieworks”.

|

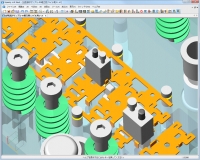

| The name of Item[2] | 3D CAD/CAM Cimatron |

| Details[2] | Cimatron realizes the smooth manufacturing from 3D models supported by features such as history, removing fillets, and modifying the geometry by parametric modeling. Powerful features reduce the time to modify models. Cimatron offers the fully supported system till 5 axis machining. Control tool paths with rich parameters: saving the machining time, and realizing a fine finishing.

|

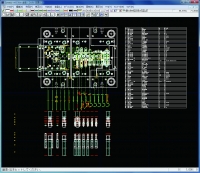

| The name of Item[3] | 2D CAD/CAM Speedy mill/Win |

| Details[3] | Bestselling and highly regarded 2D CAD/CAM specialized in press dies since 1985, It is the origin of CAMTUS. Equipping powerful features for designing press dies: flattening bendings, calculating blank shapes, and “Dieworks” menus. As for CAM, we have a reputation on Machining centers, 5-face machining centers, Wire EDM, and Laser cutting machines. We strive to do our best for improving features to offer much better operation.

|

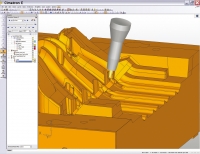

| The name of Item[4] | 2D CAD/CAM Tamago/Win |

| Details[4] | Specialized in machining, with flexibly adaptable to various machining centers. Accumulated experiences and skills for Machining centers, 5-face machining centers which require complex NC output, Multi-task machines which is essential for parts machinings, and Wire EDM. We realize the best cost-effectiveness

|

| The name of Item[5] | Quick Blank Design |

| Details[5] | features for: obtaining the area of blank shapes for an estimate, calculating the circumference of blank and the blanking force, showing the strain of board thickness, and projecting the edges of product model to the calculated blank shape.

|

| Category of Exhibit Items |

L. CAD/CAM/CAE SYSTEM CAD/CAM/CAE System |