- HOME>

- Exhibitor Search

Exhibitor Search

Exhibitor Detail

| Exhibitor name |

ダイジェット工業株式会社

DIJET INDUSTRIAL CO., LTD.

|

|---|---|

| Booth NO. | 343 |

| Address |

〒547-0002 大阪府 大阪市平野区加美東2-1-18 2-1-18, Kami-Higashi, Hirano-ku, Osaka 547-0002, Japan |

| Website | http://www.dijet.co.jp |

| info_hp@dijet.co.jp | |

| Phone number | +81-6-6791-6781 |

| FAX | +81-6-6793-1221 |

| PR message | We will exhibit new generation high efficient milling tools with double side insert, "QM MILL/QM MAX" which is lined up various type of inserts for high feed cutting, shoulder milling and finishing. We also exhibit spot facing drill TLDM/TLZD type which is applicable to various kind of spot facing. |

| The Main Item |

"QM MAX G2" GMX/MXG type with high efficient roughing.

|

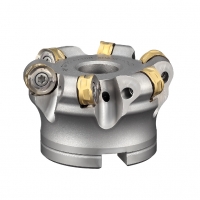

| The name of Item[1] | "QM MAX G2" GMX/MXG type with high efficient roughing. |

| Details[1] | Outperforms for high metal removal using double side 3D insert with 4 cutting edges. Insert thickness 4mm gives 1.2 times stronger than conventional tools. Possible to high feed and high efficient machining by adopting multi blades specifications. Very stable for high feed milling even in case of L/D>6. Suitable for various kind of machining; ramping, helical interpolation, and pocket milling. Lineup: Modular head 16mm - 42mm dia., Facemill 50mm - 66mm dia.

|

| The name of Item[2] | QM MILL "MIRROR INSERT" YOHW type for finishing |

| Details[2] | "QM MILL" MPM/PME type, have extensive lineup of insert YOHW type for finishing. High feed and shoulder milling can be processed with same body. Moreover, adopted "MIRROR INSERT" YOHW type achieved high efficient finishing. "MIRROR INSERT" are adopted new PVD coated grade "DH102" for high speed machining in high hardened material. Adopted PVD coated grade "JC8015" are applicable for any work materials. Corner radius: R0.3 - R0.8

|

| The name of Item[3] | Indexable Spot facing drill TLZD type |

| Details[3] | Indexable spot facing drill with point angle of 180°(flat face). Possible to reduce cost of tools only changing insert. Much economical compare with solid carbide drill especially in case large diameter. By adopting high rigid "G-body", drilling or spot facing of angled surfaces and crossed hole drilling is possible with non step machining. No need to drill prepared hole. By adopting new PVD coated grade "JC7550" and unique coolant system, achieved longer tool life even if drilling mold steel or stainless steel. Size range: 14mm - 32mm dia. (Drilling depth: 1.5D)

|

| The name of Item[4] | Spot facing drill TLDM type |

| Details[4] | Spot facing drill with point angle of 180° (flat face), have extensive lineup of 1mm - 2.9mm dia. Stable drilling without pilot hole even if drilling slope surface, cylindrical surface and crossed hole. Controlled burr in case of drilling thin plate. Due to wide flute design TLDM achieved excellent chip control. Wide application of materials such as carbon steel, mold steel, stainless steel, and aluminum alloy. Size range: 1mm - 14mm dia.

|

| The name of Item[5] | "EXTREME DIEMATE" EXTDM/MTX type, indexable radius cutter for hard-to-cut material |

| Details[5] | Milling tool with radius insert for difficult to cut material especially for turbine blade. Adopting unique helical cutting edge achieved both sharpness and rigidity of cutting edge. Possible to use double side 8 cutting edge. Economical by adopting M grade insert. Adopting wedge shaped contact between inserts and holders prevents movement of inserts. Stable machining is possible. Lineup: Modular head 32mm - 40mm dia., Facemill 50mm - 66mm dia.

|

| The name of Item[6] | "SKS EXTREME" EXSKS type, next-generation high feed machining cutter |

| Details[6] | Possible to high feed machining on fz=2mm/t in case of Max. depth of cut (ap)= 3mm. Economical double-side insert (6 corners). Insert thickness: 7.5mm improved strength by 1.5 times compared with conventional tool. Due to wedge-shaped binding face of insert, only single screw clamp prevents movement of inserts with changing corner of inserts easily. Possible to stable high feed machining in case of long overhung length over L/D=6. Excellent in ramping and helical interpolation, and possible to high efficient pocket milling. Lineup: Facemill 50mm - 160mm dia.

|

| The name of Item[7] | "GRM type" radius inserts for "MIRROR BALL" BNM/MBN type |

| Details[7] | Reduced the hand finishing and tryout times of die & mold by improved surface quality. Body durability is higher than ball nose end mill with same radius, therefore prevents chattering problem, and larger pick feed improved machining efficiency. Possible to high precision & high efficient machining even in case of general machine. Adopted new PVD coated grade "DH102" suitable for high hardened material, and PVD coated grade "JC8015" for general steel. Adopting CBN grade "JBN245" achieved high speed machining & ultra-finishing on cast iron and longer tool life. Size: 16mm dia.(R5) - 30mm dia.(R10)

|

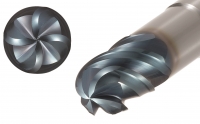

| The name of Item[8] | "ONE-CUT BALL 70", solid carbide ball nose end mill for high hardened material up to 70HRC. |

| Details[8] | Solid carbide ball nose end mill for high hardned material form roughing to finishing. High efficient machining is possible due to 4 flutes. High rigidity of tool and un-equal pitch control the vibration. Adopting unique flute geometry at the center point achieved good chip ejection & stable machining. Achieved low cutting force due to high helix angle, and provided good cutting performance. Adopted new PVD coated grade "DH102" suitable for high hardened material. Achieved longer tool life. Size range: 3mm - 12mm dia. (R1.5 - R6)

|

| The name of Item[9] | Tuff modular heads system, Solid modular head "S-HEAD for aluminum alloy" SMAL type |

| Details[9] | Solid modular head SMAL type showed the same performance as the solid end mill, by the combination with carbide shank MSN type. And, overhung length is of wide range, due to many variation in carbide shank MSN type. Adopted the cutting edge geometry suitable for aluminum alloy machining. Positive geometry with helix angle 45° & rake angle 20° achieved sharpness and high precision machining. Achieved both good chip ejection and high efficient machining due to 3 flutes. Adopting coolant hole with every flutes can be possible surely coolant supply to cutting edge, so prevented welding and improved chip ejection. Adding over size type (tool dia. > shank dia.) also enables machining at corner wall. Size range: 18mm - 32mm dia.

|

| The name of Item[10] | "CERMETAL" CT500 series for wear and impact resistant tools |

| Details[10] | In "CERMETAL" CT500 series, the grains of TiCN are cemented by a metallic binder and tungsten(W) and cobalt(C) are not included. Merits of CT500 series is good balance of hardness and toughness, good slipping and anti-galling properties, good resistance to oxidation and high strength at high temperature, light weight, low thermal conductivity, better machining performance than ceramics.

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds C. MACHINE ACCESSORY Tool Holders D. CUTTING TOOLS Cemented Carbide Tools Cemented Carbide Tips Diamond Tools Others |