Exhibitor Search

Exhibitor Detail

| Exhibitor name |

ボーラー・ウッデホルム株式会社

BOHLER-UDDEHOLM KK

|

|---|---|

| Booth NO. | 6B-1011 |

| Address |

〒102-0085 東京都 千代田区六番町2-8 番町Mビル Bancho M Building 2-8 Rokubancho, Chiyoda-ku Tokyo 102-0085 Japan |

| Website | http://www.bohler-uddeholm.jp |

| info@bohler-uddeholm.jp | |

| Phone number | +81-3-5226-3771 |

| FAX | +81-3-5226-6110 |

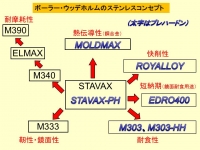

| PR message | BOHLER-UDDEHOLM KK marked its beginning in 1953 as a sales company for special steels including various types of tool steels in Japan. Its manufacturing mills, Uddeholm (Sweden) and Bohler (Austria) are world-renowned for their innovation and quality for well over a few centuries. Bohler-Uddeholm continues to play a pivotal role as the global market leader within the Tooling Industry and the high end Special Steel application field. |

| The Main Item |

Plastic Mould steels (Stavax ESR), Powder Metallurgy steels (Uddeholm SuperClean, Bohler MicroClean)

|

| The name of Item[1] | RoyAlloy |

| Details[1] | General) Uddeholm RoyAlloy is a free machining stainless holder steel, which is supplied in the pre-hardened condition. Properties) Excellent machinability, Good dimensional stability, Excellent weldability, Good corrosion resistance, Good ductility, Uniform hardness in all dimensions, Smooth as-rolled surfaces, Good indentation resistance Application) • Mould bases (holders/bolsters, cavity plates,support/backing plates, ejector plates) • Plastic and rubber moulds with low demands on surface finish • Dies for plastic extrusion • Constructional parts

|

| The name of Item[2] | ELMAX Super Clean |

| Details[2] | General) Uddeholm Elmax SuperClean has been able to achieve this unique combination of properties by SuperClean powder-metallurgy-based production. Application) Uddeholm Elmax SuperClean has the following characteristics: • High wear resistance • High compressive strength • Corrosion resistant • Very good dimensional stability Uddeholm Elmax SuperClean can be used in insert of injection molds and also in the food processing industry for industrial knives, where a combination of corrosion resistance and wear resistance is required. Uddeholm Elmax SuperClean offers a possibility to make long-life, low maintenance moulds for the best overall moulding economy.

|

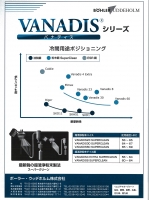

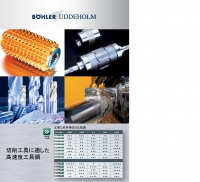

| The name of Item[3] | SUPERCLEAN/MICROCLEAN |

| Details[3] | ■General SuperClean powder metallugy process achieved highly improved properties by reduction of non-metallic inclusion. SuperClean is a trade mark of UDDEHOLM, MicroClean is a trade mark of BOHLER. ■Properties These grades can be heat treated into more than 65HRC. Good balance of compressive strength and wear resistance can imprpve the life of cutting tools which are made of AISI M42 and other HSS including Co. ■Applications *Cutting tools End mill, Hob, Broac, Drill, Tap, Industrial knife *Cold work tool Punches, Dies, and Rolls

|

| The name of Item[4] | Vanadis 23/30/60 SuperClean |

| Details[4] | ■General Vanadis 23/30/60 SuperClean are produced by SuperClean powder metallugy process, which achieves highly improved properties by reduction of non-metallic inclusion. ■Application Vanadis 23/30/60 SuperClean are high speed steels with very good abrasive wear resistance in combination with a high compressive strength. It is suitable for demanding cold work applications like blanking of harder materials like carbon steel or cold rolled strip steel and for cutting tools. The machinability and grindability are superior than for conventional high speed steel and so is the dimensional stability after heat treatment. 1 Fine blanking/ Cold forging 2 Blanking of high tensile strength sheet and electrical sheet 3 Injection molds for engineering plastics 4 Endmill, drill, Hob cutter, pinion cutter

|

| The name of Item[5] | BOHLER MICROCLEAN |

| Details[5] | We sell a lot of high quality tool steels mainly used for dies, molds and tools. P/M steel is a representative product which shows our high quality manufacturing technology. P/M steel with finely and evenly distributed carbides has the good balance of wear resistance & toughness/ ductility. We started to sell P/M steel in1970’s and have been improving its quality. Main improvement is found in the cleanliness and the size of powder. Both of them contribute to reduce the problem with chipping and galling and the longer tool life has been achieved.

|

| The name of Item[6] | STAVAX ESR |

| Details[6] | General) Uddeholm Stavax ESR is a premium grade stainless tool steel with the following properties: • good corrosion resistance • excellent polishability • good wear resistance • good machinability • good stability in hardening The practical benefits of good corrosion resistance in a plastics mould can be summarized; • Lower mould maintenance costs The surface of cavity impressions retains their original finish over extended running periods. Moulds stored or operated in humid conditions require no special protection. • Lower production costs Since water cooling channels are unaffected by corrosion, cooling efficiency are constant throughout the mould life, ensuring consistent cycle times. These benefits, coupled with the high wear resistance of Uddeholm Stavax ESR, offer the moulder low-maintenance, long-life moulds for the greatest overall moulding economy. Note: Uddeholm Stavax ESR is produced using the Electro-Slag-Refining (ESR) technique, resulting in very low inclusion content.

|

| Details[7] | Böhler-Uddeholm Group is a part of voestalpine group. Bohler-Uddeholm KK (BUKK) is belong to ASSAB Pacific (H.Q. Singapore) group which supervises the sale companies in East Asia.

|

| Details[8] | Bohler-Uddeholm Bohler-Uddeholm KK was established in 1953 as a sales company who supply European high quality special steels to Japanese market. In 2008, we built up a new warehouse at Fukuroi city, Shizuoka pref. to enhance the logistic, cutting and machining service. Our main steel mills are Uddeholm (Sweden) and Böhler (Austria). Both of them has more than 350 years history and are world-widely well-known for their customer oriented marketing activity based on the cooperation of production & sales. We are the pioneer who has installed new steel making process & technology such as, vacuum degassing, ESR, SuperClean powder metallugy, etc. We have developed a lot of highly advanced tool steels and contributed to reduce the cost of industrial parts which are manufactured by our customers. Bohler-Uddeholm group continues to play a role as the top runner in the field of tool steel, high precision strip steel and high quality special steel.

|

| Details[9] | General EDRO400™ is a remelted 400 series martensitic stainless steel supplied prehardened to approximately 40 HRC. EDRO400™ is characterized by: - Excellent polishability - Superior corrosion resistance - High level of dimensional stability - Enhanced machinability - Good ductility and toughness - Uniform and consistent hardness - Good thermal conductivity - Good resistance to indentation (compressive strength) - Smooth as rolled plate surfaces - Excellent weldability Applications - Plastic injection mold inserts / cavities - Extrusion tooling - Rubber molds - Components - Constructional parts

|

| The name of Item[10] | M303・M303HH |

| Details[10] | General M303/ M303HH are martensitic stainless steels supplied in prehardened condition. M303 is supplied at approximately 30 HRC (flat / round bar) and M303HH is supplied at approximately 40 HRC (round bar only). M303/ M303HH are characterized by: - Superior corrosion resistance - Good polishability - Good ductility and toughness - Enhanced machinability - Good resistance to indentation (compressive strength) - Possible to harden into ~50HRC Application - Plastic injection mold inserts / cavities which requires corrosion resistance - PVC fitting mold, extrusion tooling, rubber molds, mold parts, component parts - Big mold (M303: max. stock sixe 420 x1210 x L)

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Materials Mold Components H. PRESS FORMING MACHINES Servo Press Transfer Press Fine Blanking Press Deep Drawing Press Briquetting Press Forging Press J. PLASTIC FORMING MACHINES Injection Molding Machines Extruder Vacuum Forming Machines Mold Temperature Controllers N. PARTS PROCESSING TECHNOLOGY Plasticity Processing Plastic Processing Forming Processing Tooling, Steel Materials |